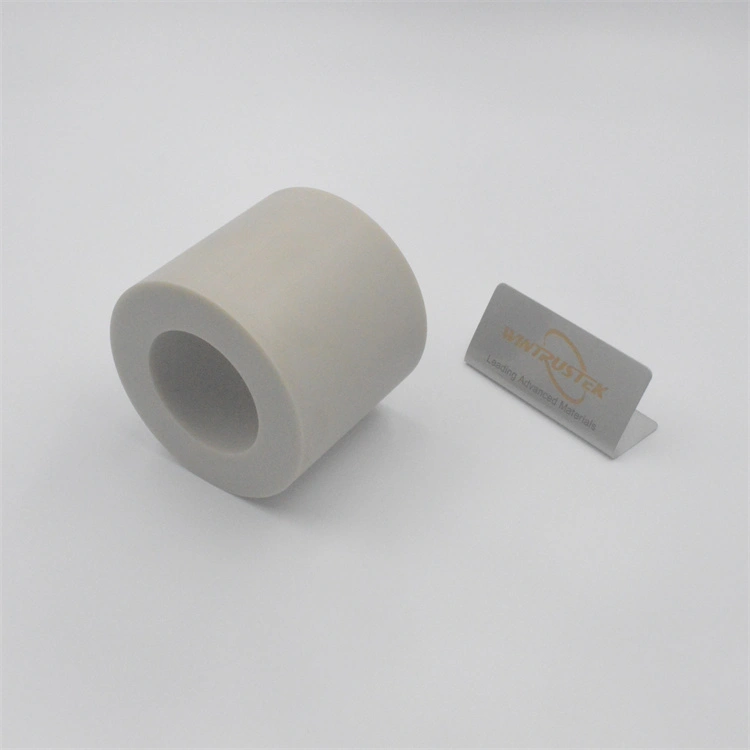

Product Description

Boron nitride ceramic parts have good heat resistance, thermal stability, thermal conductivity and high temperature dielectric strength, making them ideal for applications in heat dissipation and high temperature insulation environments.

Boron nitride ceramics are chemically stable, resistant to most molten metals, and have excellent self-lubricating properties.

Hexagonal boron nitride ceramics supplied by Wintrustek can withstand high temperatures in high vacuum environments and have excellent corrosion resistance. As a result, BN ceramic products are ideal for many industries, such as crucibles for melting semiconductors, high temperature vessels for metallurgy, semiconductor heat dissipation and insulation parts, high-temperature bearings, thermowells and glass forming abrasives

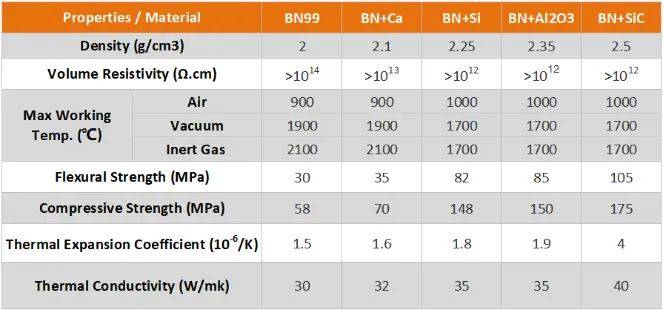

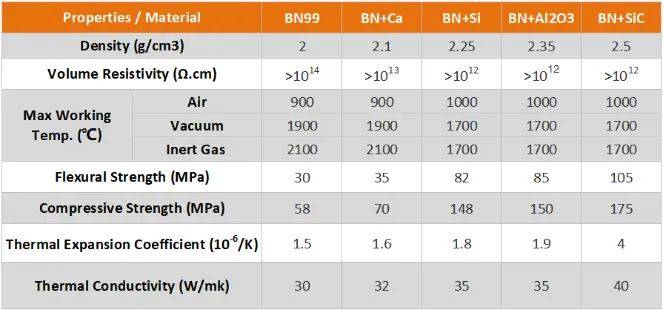

Physical Properties

✔ Heat resistant

✔ Thermally stable (up to 1000˚C in air, 1900˚ in vacuum, and 2100˚ C in an inert atmosphere)

✔ Chemical resistant

✔ Chemically inert and stable

✔ Low thermal conductivity

✔ Low thermal expansion

✔ Low dielectric constant

✔ Non-wetting (glass, salts, some metals)

✔ Self-lubricating

✔ Easily machined

✔ Electrically insulating

Applications

✔ Furnace fixture supports and components

✔ Melting crucibles for glass and metals

✔ Plasma and welding tip insulators

✔ High temp thermal complete systems

✔ Molten metal carrier pipes

✔ Nuclear reactor shields and linings

✔ Semiconductor wafers

✔ Ceramic bushings

✔ Heat radiation shielding

✔ Ceramic washers

✔ Transistor heat sinks

✔ Sputtering targets

✔ Microwave tubes

✔ Ceramic coating and paints

✔ Pump nozzles

✔ Nanotechnology

✔ Refractory molds for glass forming and titanium forming

✔ Ceramic electrical insulators

✔ Boats

✔ Thermocouple protection sheaths

Material Properties

Packaging & Shipping

Xiamen Wintrustek Advanced Materials Co., Ltd.

ADDRESS:No.987 Huli Hi-Tech Park, Xiamen, China 361009

Phone:0086 13656035645

Tel:0086-592-5716890

SALES

Email:sales@wintrustek.com

Whatsapp/Wechat:0086 13656035645