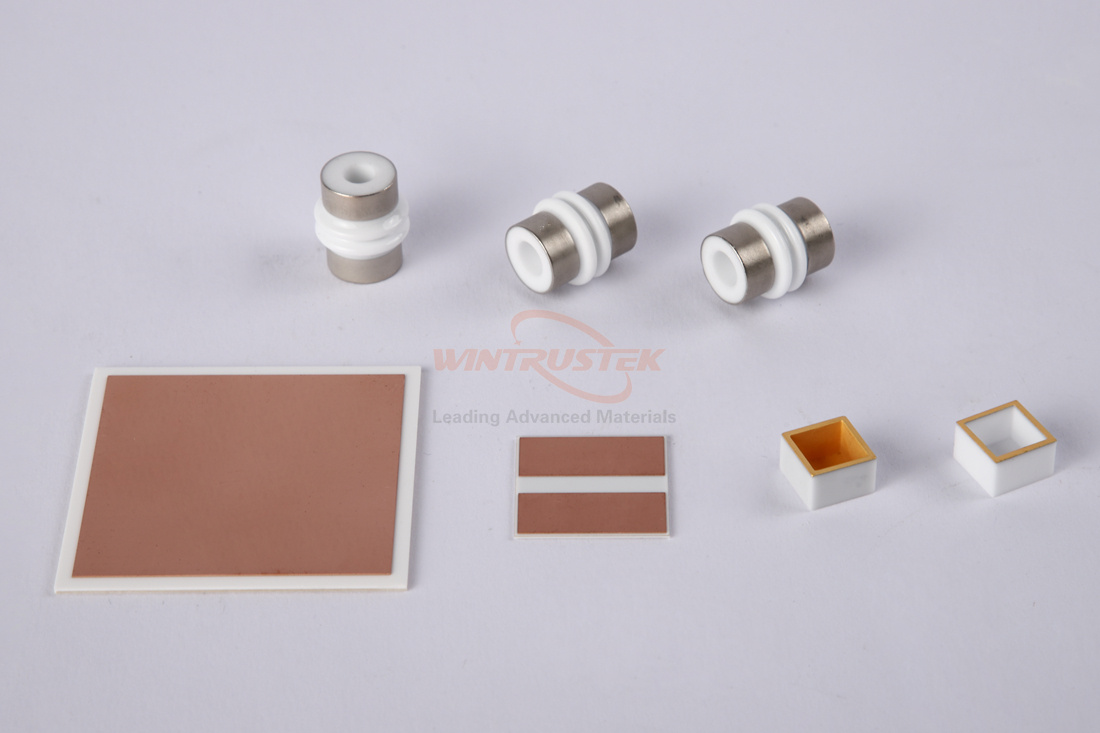

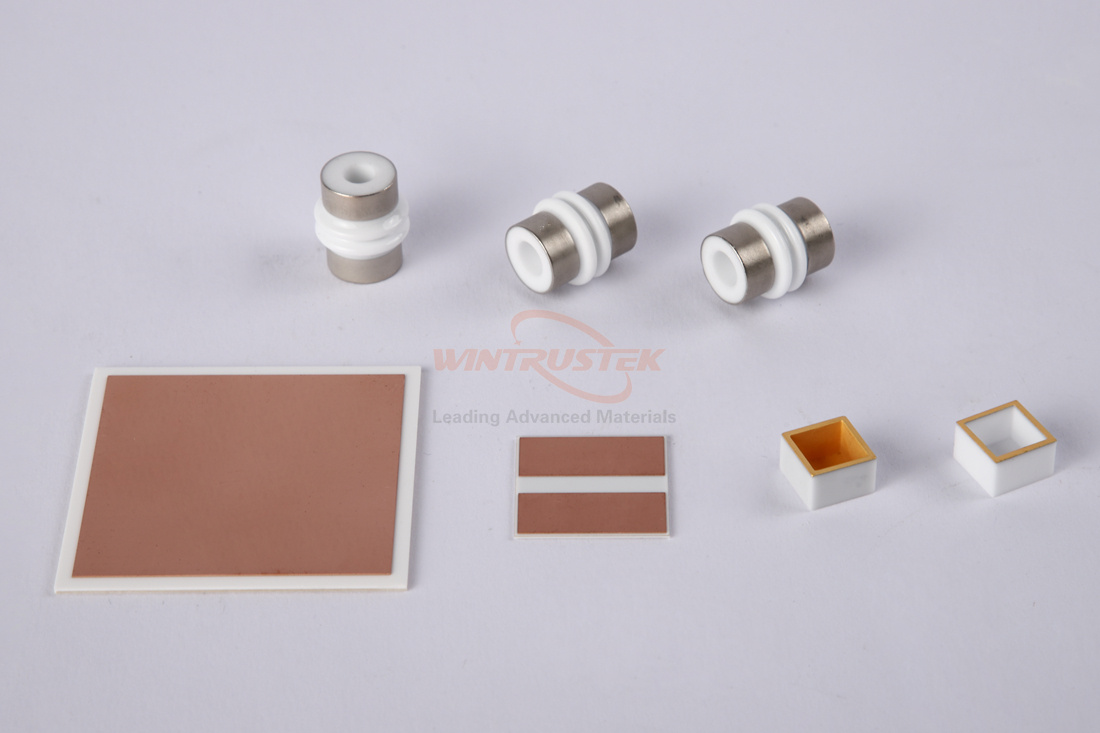

Metallized ceramics are ceramics coated with a layer of metal, allowing them to be firmly bonded to metal components. This process typically involves depositing a metal layer on the ceramic surface, followed by high-temperature sintering to bond the ceramic and metal. Common metallization materials include molybdenum-manganese and nickel. Due to ceramics' excellent insulation, high-temperature, and corrosion resistance, metallized ceramics are widely used in the electronics and electrical industries, particularly in vacuum electronic devices, power electronics, sensors, and capacitors.

Metallized ceramics are widely used in applications requiring high-temperature stability, mechanical strength, and good electrical performance. For example, they are used in lead packaging for vacuum electronic devices, substrates for power semiconductor devices, heat sinks for laser devices, and housings for high-frequency communication equipment. The sealing and bonding of metallized ceramics ensure the reliability of these devices in extreme environments.

| Available Materials | 95% 96% 99% Alumina, AlN, BeO, Si3N4 |

| Available Products | Structural Ceramic Parts and Ceramic Substrates |

| Available Metallization | Mo/Mn Metallization

Direct Bonded Copper method (DBC)

Direct Plating Copper (DPC)

Active Metal Brazing (AMB) |

| Available Plating | Ni, Cu, Ag, Au |

| Customized specifications upon your requests. |