Material Overview

Boron Carbide is a superiorly hard material (Mohs hardness > 9.36) and is one of the hardest materials known behind Diamond and cubic boron nitride. The material is sought after due to its high hardness, abrasive wear resistance, fracture toughness, chemical inertness, and important to the nuclear industry, a high neutron absorbing cross section. Boron Carbide powders can be used for reaction bonded, hot-pressed or sintered ceramic applications. The material is therefore well suited for technical ceramics, wear parts, and other industrial parts such as body and vehicle armor. Other uses include refractory additives and honing sticks.

Boron Carbide is produced by the reaction of Boron Trioxide and Carbon at high temperatures in an electric arc furnace. The material is then milled and purified.

Wintrustek offers the Boron Carbide according to FEPA F Standards in a wide range of grit sizes.

Typical Features

High Hardness

Excellent Abrasion Resistance

High Fracture Toughness

Chemical Inertness

High Neutron Absorbing Cross Section

Applications

High-temperature thermoelements

Boron source to produce other boron compounds

Abrasive grit or powder (grinding, lapping, polishing)

Lightweight ceramic armor

Neutron shielding material

Metal infiltration

Hot-pressed and sintered ceramic parts

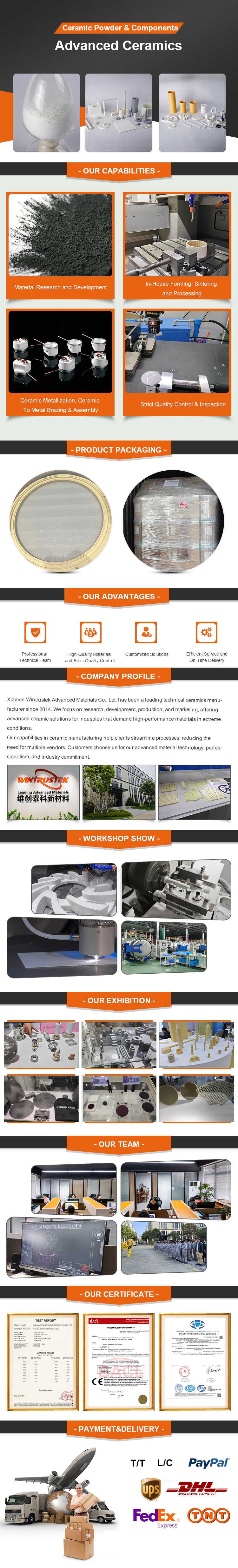

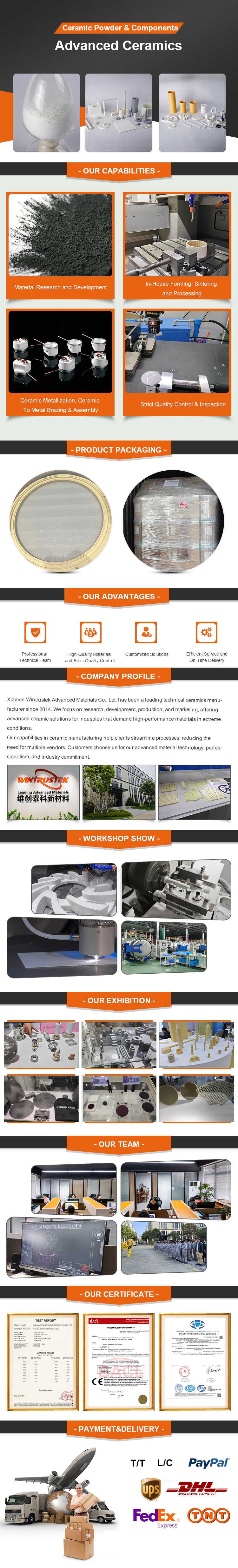

Wintrustek Advanced Materials is a leading ceramic powder supplier. We provide high-quality Boron Carbide ceramic powder and abrasive at a competitive price.

More Materials

Our Ceramic Powders include:

Boron Nitride (BN) Powder

Boron Carbide (B4C) Powder

Aluminum Nitride (AlN) Powder

Xiamen Wintrustek Advanced Materials Co., Ltd.

ADDRESS:No.987 Huli Hi-Tech Park, Xiamen, China 361009

Phone:0086 13656035645

Tel:0086-592-5716890

SALES

Email:sales@wintrustek.com

Whatsapp/Wechat:0086 13656035645