Aluminum Nitride (AlN) was first synthesized in 1877, but its potential application in microelectronics did not spur the development of high-quality, commercially viable material until the mid-1980s.

AIN is an aluminum nitrate form. Aluminum nitride differs from aluminum nitrate in that it is a nitrogen compound with a specific oxidation state of -3, while nitrate refers to any ester or salt of nitric acid. This material's crystal structure is hexagonal wurtzite.

Synthesis of AIN

AlN is produced through either the carbothermal reduction of alumina or the direct nitridation of aluminum. It has a density of 3.33 g/cm3 and, despite not melting, dissociates at temperatures above 2500 °C and atmospheric pressure. Without the assistance of liquid-forming additives, the material is covalently bonded and resistant to sintering. Typically, oxides such as Y2O3 or CaO permit sintering at temperatures between 1600 and 1900 degrees Celsius.

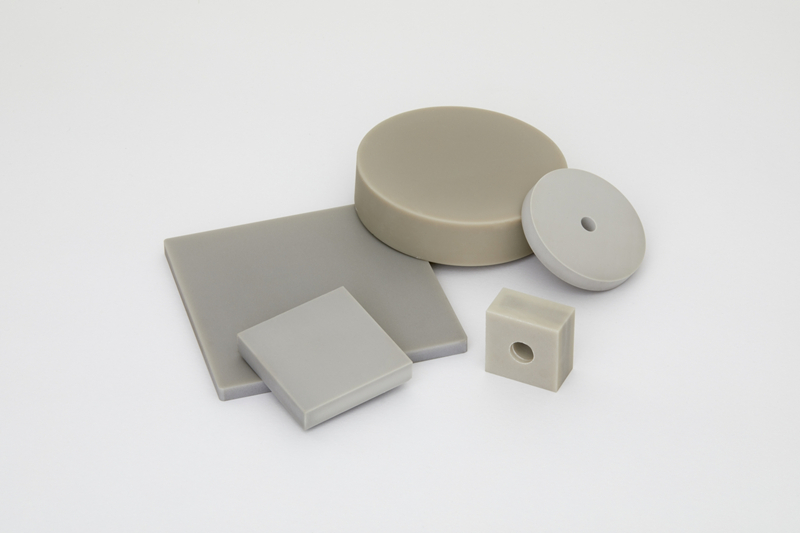

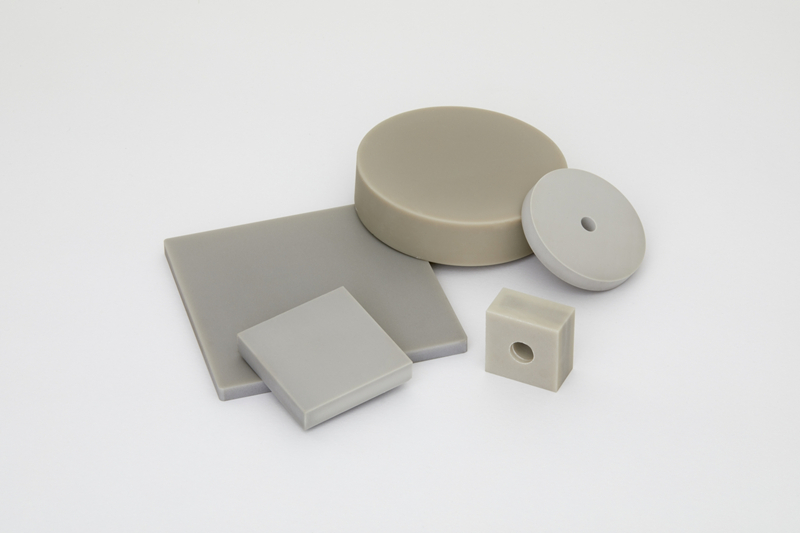

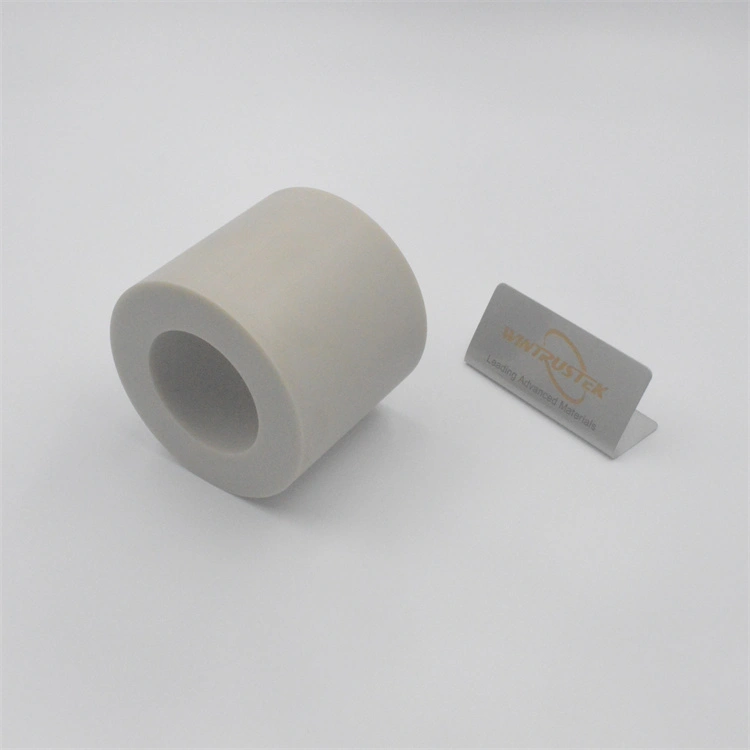

Parts made of aluminum nitride can be manufactured via a variety of methods, including cold isostatic pressing, ceramic injection molding, low-pressure injection molding, tape casting, precision machining, and dry pressing.

Key Features

AlN is impervious to most molten metals, including aluminum, lithium, and copper. It is impervious to the majority of molten salts, including chlorides and cryolite.

Aluminum nitride possesses high thermal conductivity (170 W/mk, 200 W/mk, and 230 W/mk) as well as high volume resistivity and dielectric strength.

It is susceptible to hydrolysis in powder form when exposed to water or humidity. Additionally, acids and alkalis attack aluminum nitride.

This material is an insulator for electricity. Doping enhances the electrical conductivity of a material. AIN displays piezoelectric properties.

Applications

Microelectronics

The most remarkable characteristic of AlN is its high thermal conductivity, which is second only to beryllium among ceramic materials. At temperatures below 200 degrees Celsius, its thermal conductivity surpasses that of copper. This combination of high conductivity, volume resistivity, and dielectric strength enables its use as substrates and packaging for high-power or high-density microelectronic component assemblies. The need to dissipate heat generated by ohmic losses and maintain the components within their operating temperature range is one of the limiting factors that determine the density of packing of electronic components. AlN substrates provide more effective cooling than conventional and other ceramic substrates, which is why they are used as chip carriers and heat sinks.

Aluminum nitride finds widespread commercial application in RF filters for mobile communication devices. A layer of aluminum nitride is located between two layers of metal. Common applications in the commercial sector include electrical insulation and heat management components in lasers, chiplets, collets, electrical insulators, clamp rings in semiconductor processing equipment, and microwave device packaging.

Other Applications

Due to the expense of AlN, its applications have historically been limited to the military aeronautics and transportation fields. However, the material has been extensively studied and utilized in a variety of fields. Its advantageous properties make it suitable for a number of important industrial applications.

AlN's industrial applications include refractory composites for handling aggressive molten metals and efficient heat exchange systems.

This material is used to construct crucibles for the growth of gallium arsenide crystals and is also utilized in the production of steel and semiconductors.

Other proposed uses for aluminum nitride include as a chemical sensor for toxic gases. Utilizing AIN nanotubes to produce quasi-one-dimensional nanotubes for use in these devices has been the subject of research. In the past two decades, light-emitting diodes that operate in the ultraviolet spectrum have also been investigated. The application of thin-film AIN in surface acoustic wave sensors has been evaluated.