Boron Carbide (B4C) is a durable ceramic composed of Boron and carbon. Boron Carbide is one of the hardest substances known, ranking third behind cubic Boron nitride and diamond. It is a covalent material utilized in a variety of crucial applications, including tank armor, bulletproof vests, and engine sabotage powders. In fact, it is the preferred material for a variety of industrial applications. This article provides a summary of Boron Carbide and its advantages.

What exactly is Boron Carbide?

Boron Carbide is a crucial chemical compound with a crystal structure typical of icosahedral-based borides. The compound was discovered in the nineteenth century as a byproduct of metal boride reactions. It was not known to have a chemical formula until the 1930s, when its chemical composition was estimated to be B4C. The X-ray crystallography of the substance shows that it has a very complicated structure made up of both C-B-C chains and B12 icosahedra.

Boron Carbide possesses extreme hardness (9.5–9.75 on the Mohs scale), stability against ionizing radiation, resistance to chemical reactions, and excellent neutron shielding properties. The Vickers hardness, the elastic modulus, and the fracture toughness of Boron Carbide are almost the same as those of diamond.

Due to its extreme hardness, Boron Carbide is also referred to as "black diamond." It has also been shown to possess semiconducting properties, with hopping-type transport dominating its electronic properties. It is a p-type semiconductor. Because of its extreme hardness, it is considered a wear-resistant technical ceramic material, making it suited for processing other extremely hard substances. In addition to its good mechanical properties and low specific gravity, it is ideal for making lightweight armor.

Production of Boron Carbide Ceramics

Boron Carbide powder is commercially produced through either fusion (which involves reducing Boron anhydride (B2O3) with carbon) or magnesiothermic reaction (which involves causing Boron anhydride to react with magnesium in the presence of carbon black). In the first reaction, the product forms a sizable egg-shaped lump at the center of the smelter. This egg-shaped material is extracted, crushed, and then milled to the appropriate grain size for final use.

In the case of the magnesiothermic reaction, stoichiometric Carbide with low granularity is obtained directly, but it has impurities, including up to 2% graphite. Because it is a covalently bonded inorganic compound, Boron Carbide is difficult to sinter without applying heat and pressure simultaneously. Because of this, Boron Carbide is often made into dense shapes by hot pressing fine, pure powders (2 m) at high temperatures (2100–2200 °C) in a vacuum or inert atmosphere.

Another method for producing Boron Carbide is pressureless sintering at a very high temperature (2300–2400 °C), which is close to the melting point of Boron Carbide. To help reduce the temperature required for densification during this process, sintering aids like alumina, Cr, Co, Ni, and glass are added to the powder mix.

Applications of Boron Carbide Ceramics

Boron Carbide has many different applications.

Boron Carbide is used as a lapping and abrasive agent.

Boron Carbide in powder form is ideally suited for use as an abrasive and lapping agent with a high rate of material removal when processing ultra-hard materials.

Boron Carbide is used to manufacture ceramic blasting nozzles.

Boron Carbide is extremely resistant to wear, making it an excellent material for blasting nozzles when sintered. Even when used with extremely hard abrasive blasting agents such as corundum and silicon Carbide, the blasting power remains the same, there is minimal wear, and the nozzles are more durable.

Boron Carbide is used as a ballistic protection material.

Boron Carbide provides comparable ballistic protection to that of armored steel and aluminum oxide but at a much lower weight. Modern military equipment is characterized by a high degree of hardness, compressive strength, and a high modulus of elasticity, in addition to low weight. Boron Carbide is superior to all other alternative materials for this application.

Boron Carbide is used as a neutron absorber.

In engineering, the most important neutron absorber is B10, used as Boron Carbide in nuclear reactor control.

The atomic structure of boron makes it an effective neutron absorber. In particular, the 10B isotope, present in around 20% of its natural abundance, has a high nuclear cross-section and can capture the thermal neutrons that are generated by the fission reaction of uranium.

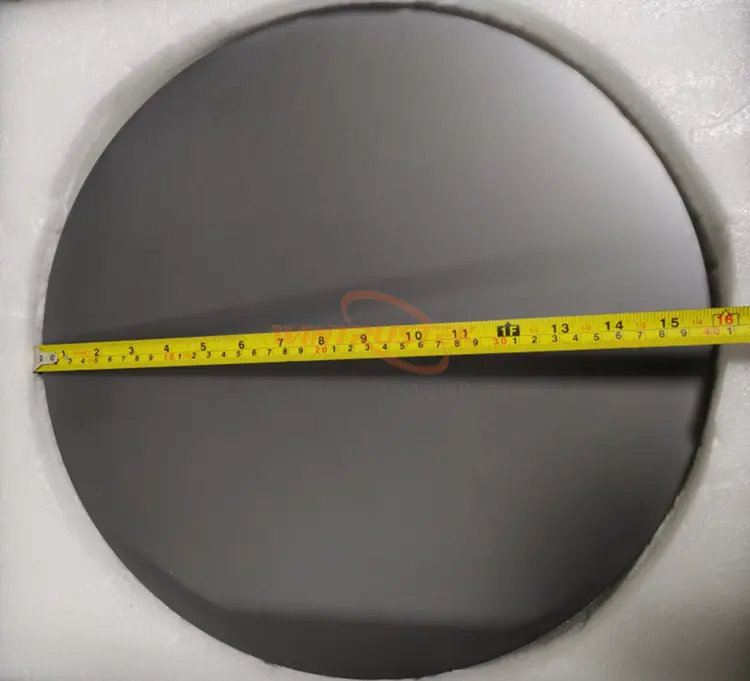

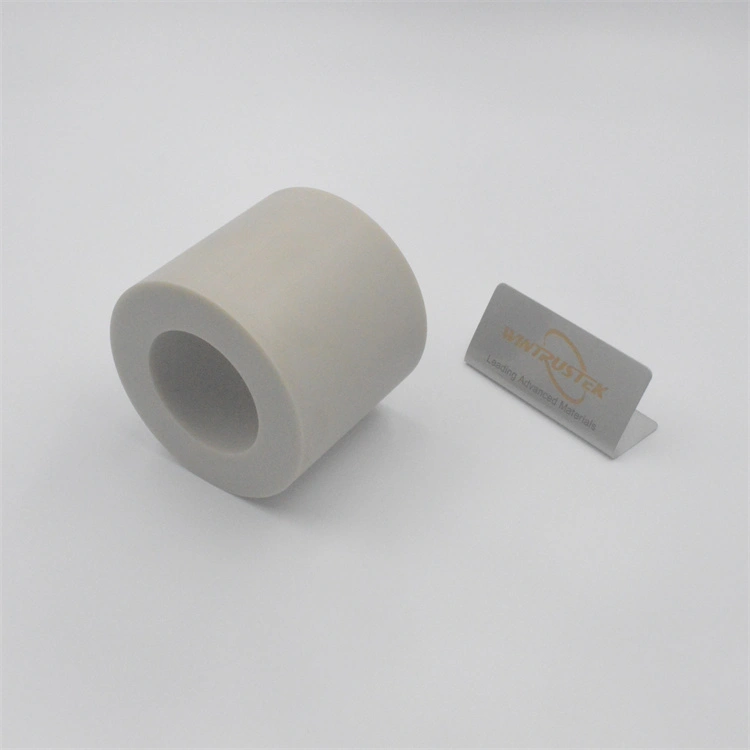

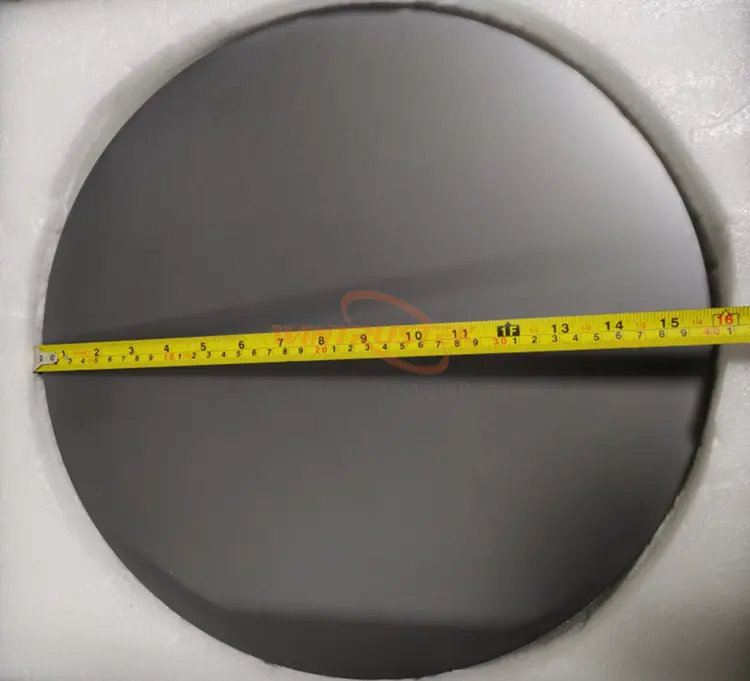

Nuclear Grade Boron Carbide Disc For Neutron Absorption