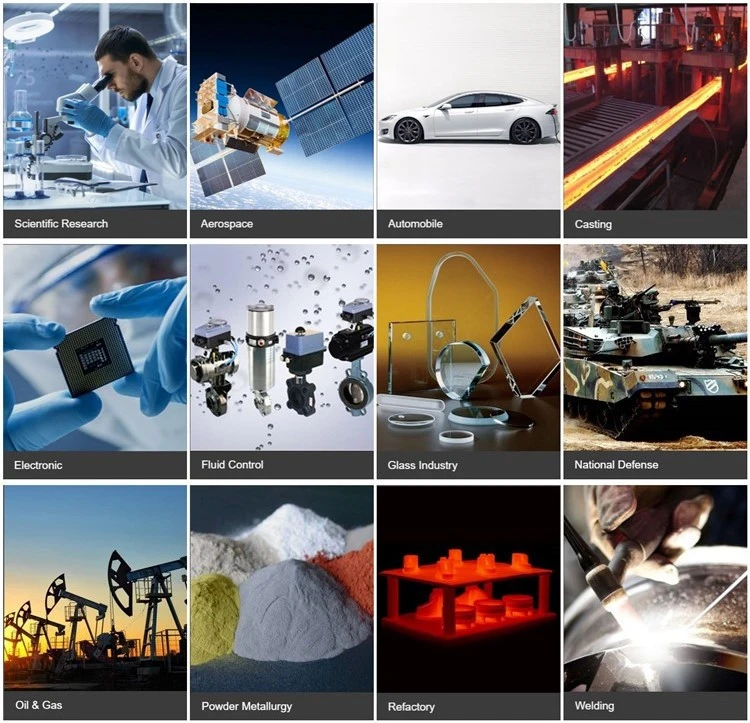

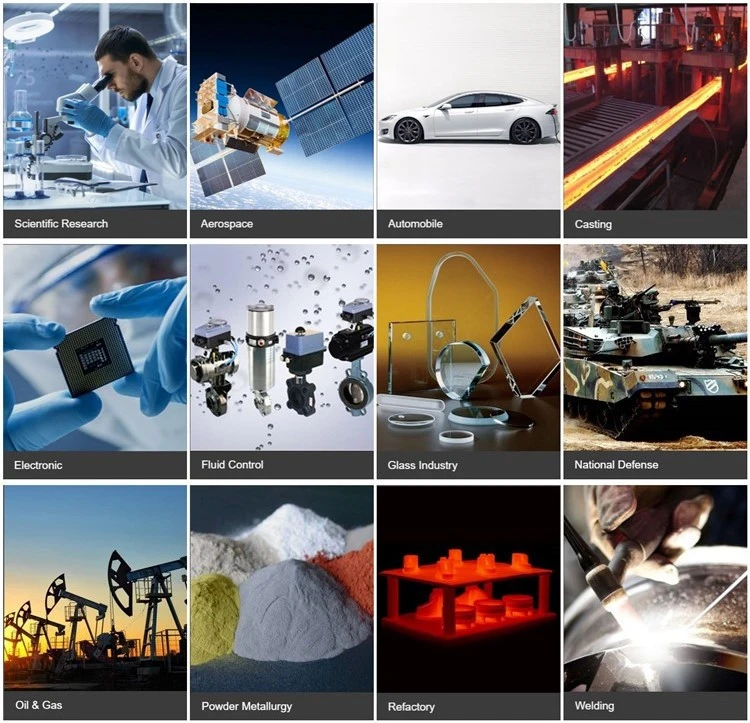

Few people are aware of how many industries use technical ceramics on a daily basis. Technical ceramics are versatile substances that can be utilized in numerous industries for a variety of fascinating purposes. Technical ceramics were designed for a variety of applications.

Because you are unaware of the material's versatility and do not realize that technical ceramics can be used in your industry, you may not even realize that your business could flourish if you begin collaborating with one of the leading technical ceramics companies. It's time to change that and examine all the industries that benefit from the unique properties of technical ceramics.

In which industries are technical ceramics used?

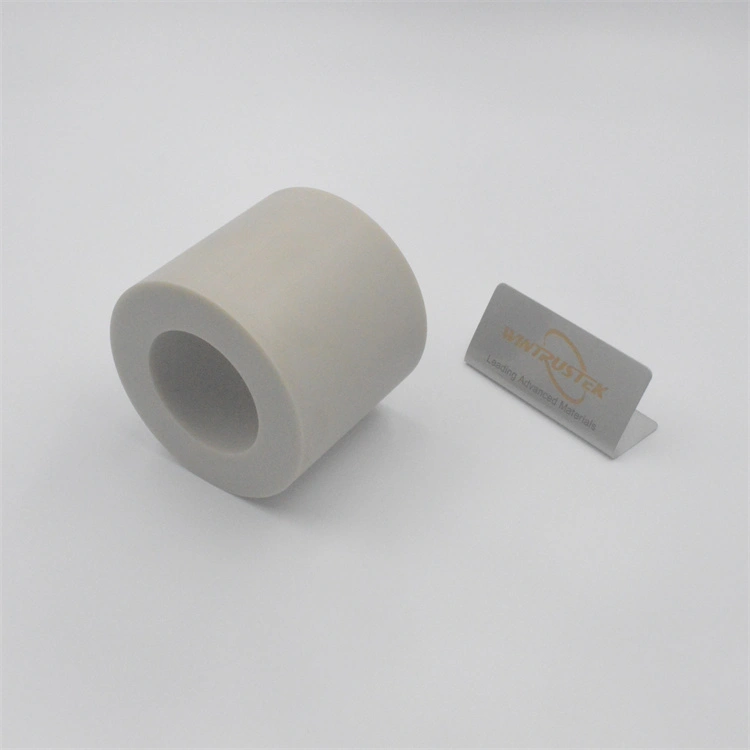

The incredible properties of technical ceramics include excellent wear resistance, superior thermal properties, high strength, low density, etc. This increases the viability of technical ceramics in a variety of industries.

Solar industry

In the solar industry, technical ceramics are an extremely popular material. They are highly resistant to temperature and corrosion, extremely durable, and highly conductive.

These characteristics make industrial ceramics essential materials for producing numerous solar industry products, including solar panels, collectors, cells, and batteries.

Aerospace industry

Numerous desirable properties of technical ceramics make them ideal for aerospace applications. These characteristics include low weight, resistance to ultrahigh temperatures, corrosion resistance, chemical stability, electrical insulation, and excellent wear resistance.

When it comes to aerospace applications, technical ceramics are primarily used for thermal protection shields, exhaust and engine systems, and turbine components, and to provide structural support for objects designed to fly at extremely high speeds.

Automotive industry

In the automotive industry, the excellent durability and high-temperature resistance of technical ceramics, among many other characteristics, are the primary reasons for their use. In the automotive industry, two fundamental types of industrial ceramic components exist:

Functional ceramics: In functional components such as oxygen sensors, sparks, glow plugs, knocking sensors, PTC heaters, parking distance control, fuel injection systems, etc., technical ceramics are utilized.

Structural ceramics: Automotive structural components such as brake discs, catalyst support, pump components, particulate filters, etc. are manufactured using technical ceramics.

Electronics industry

Without technical ceramics, this $4.5 trillion market would not exist. Almost every electronic device you own, including computers, smartphones, and televisions, contains ceramic components. In the electronics industry, technical ceramics are indispensable due to their insulating, semiconducting, superconducting, magnetic, and piezoelectric characteristics.

Technical ceramics can be found in capacitors, inductors, circuit protection devices, displays, audio systems, and numerous other electronic components. Modern electronics would not exist without technical ceramics.

Oil and gas industry

Equipment for the oil and gas industry must function optimally in corrosive and abrasive environments. Therefore, technical ceramics are ideal for such applications. Technical ceramics can withstand high temperatures and intense pressure, making them ideal for use in this industry.

In addition, due to the high customizability of ceramics and the versatility this provides, an experienced manufacturer of technical ceramics can produce a compound with properties suitable for the intended application. This makes technical ceramics an excellent option for the majority of the oil and gas industry's requirements.

Food service industry

The food-safe properties of technical ceramics make them an excellent option for the food service industry. Dosing units, dosing slides, valve guides and seats, limit stops and grippers, as well as forming tools, contain ceramics.