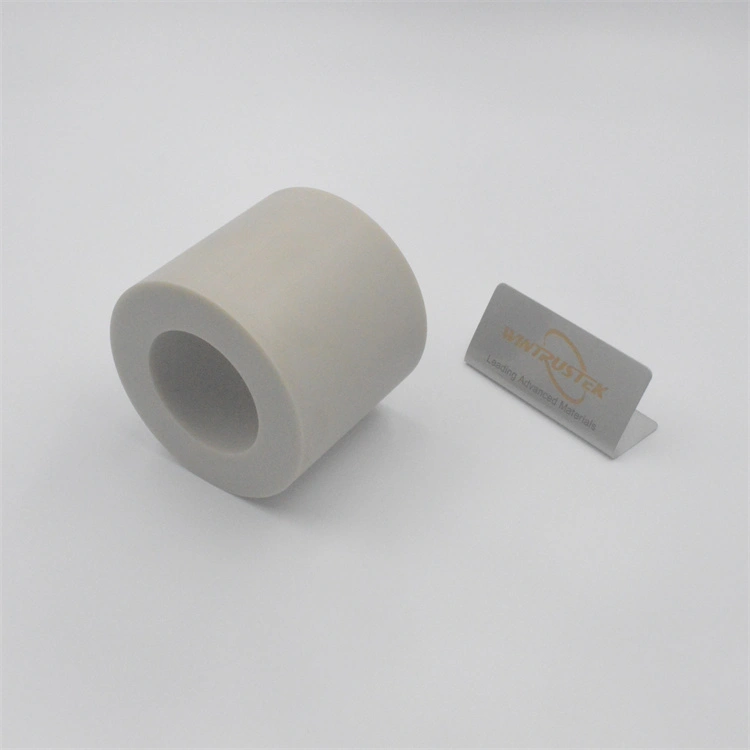

(I-DBC ceramic substrateKukhiqizwa nguI-WintrustEk)

I-Cuery Bonded Copper (DBC) Rumbemic substratesUhlobo olusha lwezinto ezihlanganisiwe lapho insimbi yethusi ikhonjiswa khona i-alumina (Al2o3) noma i-aluminium nitride (ALN) i-Ceramic Substrate. Ubuchwepheshe bensimbi yensimbi engaphezulu kwe-Alumina ne-Aluminium nitride subramic substrates cishe bufana. Ukuthatha i-Al2o3 Ceramic Subrestrate njengesibonelo, i-foil ye-CU yethusi ifakwe ngqo kwi-alumina substrate ngokushisa i-ceramic substrate esimweni se-nitrogen n2 equkethe umoya-mpilo.

Ukushisa kwezemvelo emazingeni okushisa aphezulu (1065-1085) kubangela ukuba insimbi yethusi iye ku-oxidize, incipha, futhi incibilikisa i-eusectic ye-ceramic, ebopha i-ceramic composite yensimbi yensimbi; Ngemuva kwalokho lungiselela umugqa ufaka kabusha indlela etching ngokuya ngokuthuthukiswa kwamafilimu okuvezwa komugqa. Ngokuyinhloko esetshenziswa ekuhlanganiseni kwamamojula we-semiconductor, eziqandisini kanye nezimpawu zokushisa eziphakeme.

Amabhodi wesifunda amakhompyutha kanye nemishini yamandla asekhaya aphansi ngokuvamile asebenzisa insimbi yensimbi kanye ne-organic substrates; Kodwa-ke, izinto zokwenziwa kabusha ze-ceramic ezinezinto ezingcono kakhulu ezishisayo, njenge-silicon nitride, i-aluminium nitride, kanye ne-alumina, zidingeka kumamojula aphezulu, izicelo zamandla, ezinjengamamojula wamandla, kanye nabalawuli be-solar, kanye nabalawuli bezimoto.

Le khasiI-DBC SubstrateKubuchwepheshe bemodyuli ye-Power electronic module ikakhulukazi ama-chips (Igbt chips, ama-diode chips, ukumelana, ama-spic chips, njll.), TheI-DBC SubstrateNgokusebenzisa indawo ehlanganayo yethusi, ukuqedela ingxenye ye-chip yesigxobo sokuxhuma noma sokuxhuma ingaphezulu kokuxhumeka, umsebenzi ufana neye-PCB substrate. I-DBC substrate inezindawo ezinhle zokufaka i-inforties, ukusebenza okuhle kokushisa kokushisa, ukumelana okushisayo okuphansi kanye ne-coefficient ebanzi efanisiwe.

Le khasiI-DBC SubstrateInezici ezivelele ezilandelayo: Ukusebenza okuhle kokufakwa, ukusebenza okuhle kokushisa okushisayo, ukumelana okushisayo okushisayo okuhlanganisiwe, okuhambisana nokukhiqizwa kwe-coeffient, ukusebenza okuhle kwemishini kanye nokusebenza okuhle kwe-solder.

1. Ukusebenza okuhle okufaka ukufakwa. UsebenzisaI-DBC SubstrateNjengoba ukusekelwa kwe-chip kuhlukanisa ngempumelelo i-chip kusuka kwisisekelo se-module dissipation ye-module, i-DBC substrate phakathi kwesendlalelo se-Al2o3 Ceramic noma ungqimba we-ALN CERAMIC ithuthukisa amandla we-module infathing (i-Curamic ungqimba lokungena ngaphakathi kwe-2.5kv).

2. Ukusebenza okuhle kakhulu okushisayo, TheI-DBC SubstrateInokuvuka okuhle kakhulu okushisayo okungu-20-260w / mk, module we-IGBT kwinqubo yokusebenza, ingaphezulu le-chip lizokhiqiza inani elikhulu lokushisa elingadluliselwa nge-silico esezingeni eliphansi le-module echibini lokushisa, ukuqedela ukugeleza okushisayo okuphelele kwemodyuli.

3. Ukusebenza kukagesi okuvelele. Njengoba ithusi liyinsimbi ephethe kakhulu, amasiginali kagesi angathwalwa ngokuvimbela okuncane ngokuxhumeka okuqondile phakathi kwethusi ne-substrate. Ngenxa yalokhu, i-DBC ilungele ukusetshenziswa kwemishini kagesi enesivinini esikhulu esidinga ukudlulisa idatha ngokushesha nangokuthembekile, kufaka phakathi amakhompyutha namaseva.

4. I-coefficie ekhuphukayo yeI-DBC substrateKuyafana nalokho kweChip.I-Coefficient ye-DBC substrate iyafana naleso se-silicon (I-Chip's Main Material yi-Silicon) (7.1PPM / K), kanye namandla we-DBC extrate's Chip> 20N / MM2. Ngaphandle kwalokho, futhi inezakhiwo ezinhle zemishini nokumelana nokugqwala. I-DBC ayilula ukulimala, futhi ingasetshenziswa ngaphezu kobubanzi bokushisa obubanzi.

20N / MM2. Ngaphandle kwalokho, futhi inezakhiwo ezinhle zemishini nokumelana nokugqwala. I-DBC ayilula ukulimala, futhi ingasetshenziswa ngaphezu kobubanzi bokushisa obubanzi.5. Ukusebenza kwe-Welding kuhle. Ukusebenza kwe-welding kweI-DBC substrate

kuhle. Isilinganiso se-soldering avent singaphansi kwama-5%, futhi i-DBC substrate inengqimba enkulu yethusi engamelana nomthwalo ophakeme kakhulu wamanje. Esigabeni esifanayo sesiphambano, imvamisa idinga kuphela i-12% ye-PCB's Purnive Found, khona-ke ingadlulisela amandla amaningi kwivolumu yeyunithi ukwenza ngcono ukuthembeka kohlelo nokwenziwa kwemishini. Ngenxa yokusebenza kwazo okuhle, ama-substrates e-DBC asetshenziswa kabanzi lapho kulungiswa izinhlobo ezahlukahlukene zama-semiconductors aphezulu, ikakhulukazi izinto zokupakisha ze-IGBT.