(I-Curamic evuthayoKukhiqizwa nguI-WintrustEK)

Ngokusho kwesichazamazwi, ama-brazing "ukujoyina izingcezu ezimbili zensimbi ngokufaka ungqimba lwethusi noma i-spelter phakathi kwezindawo ezihlanganayo." Kungenzeka kube okususelwa eTrench Term kusuka ngekhulu le-16 elisho ukuthi "ukushisa."

Ngamafuphi, i-braze incibilika futhi igeleze phakathi kwezingcezu ezimbili zezinto ezibonakalayo ngesikhathi sokusebenza. Imvamisa okubizwa ngokuthi "ukumanzisa," le nqubo ibalulekile, ikakhulukazi lapho ama-ceramics. Kulezi zinsuku, izinto ezahlukahlukene zingabekelwa phansi ukudala amalunga phakathi kwazo; Izinto ezincibilikayo emazingeni okushisa ngenhla kuka-450 ° C zaziwa njengezifumbathi, kuyilapho lezo zincibilika emazingeni okushisa angaphansi kuka-450 ° C zaziwa njengezamasosha.

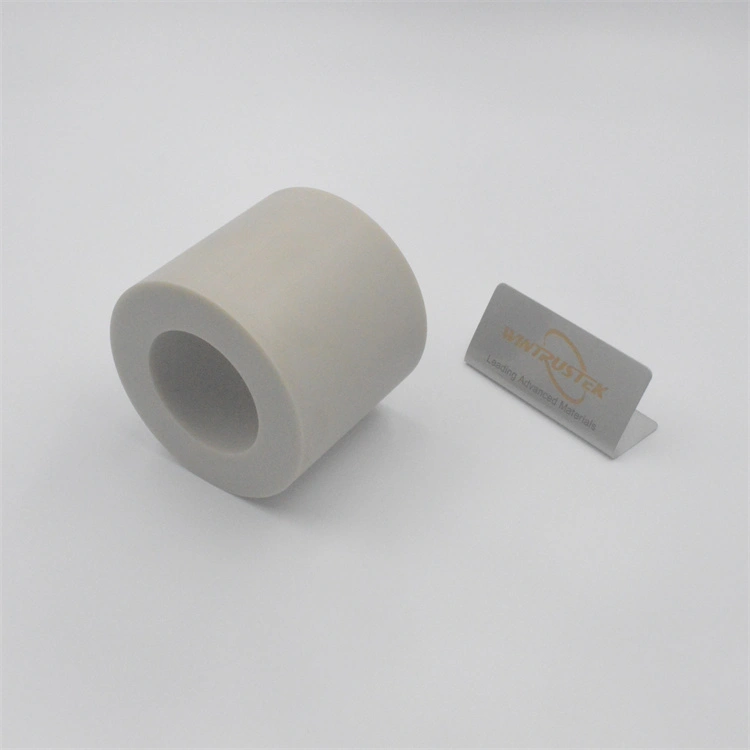

Indlela esunguliwe ye-Bonding Ceramics, i-Brazing yinqubo yesigaba se-liquid esebenza kahle kakhulu ngokwakha amalunga nezimpawu. Izakhi ezisetshenziswa kwizimboni ze-elekthronikhi nasezithukweni zezimoto, ngokwesibonelo, zingakhiqizwa kalula kusetshenziswa inqubo yokubhuqa.

Njengoba wonke umuntu ekwaziyo, ubumbahema nobumba bunokubekezelela okulinganiselwe kokuxineka okuthe xaxa futhi bangenamikhawulo futhi baqinile. Futhi bane-acticity encane. Ngakho-ke, ama-ceramics adazwa ukuthi agcizelelwe ngaphansi kokucindezelwa uma kungenzeka. Batholakala ekushashweni okushisayo noma ngabe baqashwa njengabathambisi bezinhlanzi ezishisayo. Kodwa-ke, manje sesingashintsha lezi zici ukuze zivumelane nezinhloso ezithile, ikakhulukazi ngokungeza imicu, ama-whiskers, noma ezinye izinhlayiya ezikhuthaza kakhulu (ukuqiniswa). Ngokwengeziwe, bangathuthukisa ukufaneleka kwabo ngezinhlelo ezahlukahlukene zokusebenzisa izinguquko ezibangelwa inqubo.

Umehluko oyinhloko phakathiAma-Ceramics ama-Curamicskanye nezinsimbi ukuthi ubumba ama-ceramics abushunyiswa iningi lezinto zokwakha ezijwayelekile. Lokhu kungenxa yalezi zimpawu zomzimba ezisisekelo sezinto ezibalulekile, ezinjengezibopho zazo ezinamandla ezinamandla nezama-Ionic. Ngaphezu kwalokho, kunzima ukudala ukuxhumana okuqinile kwamakhemikhali ukwenza ngcono ukunamathela njengoba ubuciko bungazinza ngokwengeziwe kwezinsimbi. Amasu ahlukahlukene angasetshenziswa ukudala amalunga amukelekile, ama-brazing-ceramic kungenzeka ukuthi asemqoka kakhulu futhi aguquguqukayo ekusetshenzisweni okukhulayo kwamanje kwama-ceramics ngenxa yokubaluleka kwawo komnotho ngenxa yokubaluleka kwawo komnotho ngenxa yokubaluleka kwabo kwezomnotho. I-ceramics yangaphambilini yasebenza ngempumelelo ekushiseni kwamakamelo, kukhombisa ukumelana nokugqoka kanye nezimfanelo ezifaka i-inculating (ngaphandle kokushaqeka).

Udaba lokubhekana nezimo zenkonzo emazingeni okushisa aphezulu ezindaweni zokufaka umoya noma ezilonakalisayo ezinezici ezibalulekile zemishini zagqugquzela ukudala izinhlobo zezinhlobo ezinobunzima.

Kukhona i-push eqinile yokuthuthukisa izinhlelo zokusebenza ze-ceramic ezinjini ezishisayo kanye nezitshalo zokushintsha ukushisa okukhiqizayo ugesi. Bonke bangadinga ama-brazing ceramic. I-ceramic nge-CEAMI enobubanzi bezinsimbi eziphansi ezandiswayo ayijwayelekile kakhulu futhi kwenzeka into emukelekile yokuqedela ngempumelelo ama-brazing-ceramic. Ukuqamba amalunga okufanele agcizelelwa ngaphansi kwengcindezi kuyindlela eyodwa esetshenziselwa ukuvala igebe kumanani we-CTE. Ngenye indlela, lapho amanani e-CTE ahlakazeka kakhulu, ukusetshenziswa kwezinto eziphakathi nendawo kunganikeza ushintsho olumnene kusuka kokuphansi kuya kwenani eliphakeme lesakhiwo.

Izindlela ezilandelayo ziqashwa ukukhuthaza ukuqina kwensimbi yensimbi yama-ceramics kanye nokubambelela komhlaba:

1. IngaqondileBrazing-CeramicKubandakanya ukufaka into yokuqala, imvamisa, kuya ebusweni be-ceramic ekuhlanganiseni okungenziwa nge-filler metal ngaphandle kokuncipha kwe-ceramic surface.

I-Metallic Coatic isebenza njengento ebopha igebe phakathi kwe-ceramic nensimbi. Ukunakekelwa kumele kuthathwe ukuvikela ubumba ngenxa yokuqhekeka yi-coating eyonaka ukushisa.

I-coating eyaziwayo ye-molybdenum-manangese ijwayelekile kuleli klasi. Ukupenda i-ceramic, kusetshenziswa ingxube yama-powders enziwe ngokukhethekile.

Emva kwalokho, ishisiwe cishe ngo-1500 ° C (2730 ° F) esithandweni semvelo se-hydrogen, esidonsa izinto ze-Ceramic ze-Curamic ukufudukela kufulawa wensimbi bese uyinamathisela ebusweni.

Okwezinsimbi ezixakile, ezinye izindlela ezisebenzayo zenhlamba zisebenzisa umdwebo we-VAPOR (PVD). Ngemuva kwalokho, ama-brazing-ceramic wenziwa kusetshenziswa izinsimbi ezijwayelekile ze-brazing filler ezifanele ngensimbi edinga ukuxhunywa.

2. Kusetshenziswa izinsimbi ezisebenzayo ze-filler ezinezinto ezihlukile zokuqamba ze-Curamic ngqo. Ukumanzisa nokunamathela kuthuthukiswa lapho izinsimbi ezinobumbano oluphezulu lwezinto zase-ceramic zengezwa kuma-alloys asekelwe kusesiliva asekelwe kwisiliva.

Ngenxa yalokhu, izinsimbi ezisabela ngokuqinile ngo-oxygen, njenge-titanium, i-aluminium, i-zithinium, i-safnium, i-lithium, i-silico, noma i-manganese, zisiza ama-brazing alloys anamathela ku-ceramics ye-oxide ngaphandle kokulungiselela kwangaphambilini.

I-Wetting Carbito Carbide noma iSilicon Nitride isizwa ngezinsimbi ezisabela nge-silico, ikhabhoni noma noma i-nitrogen.