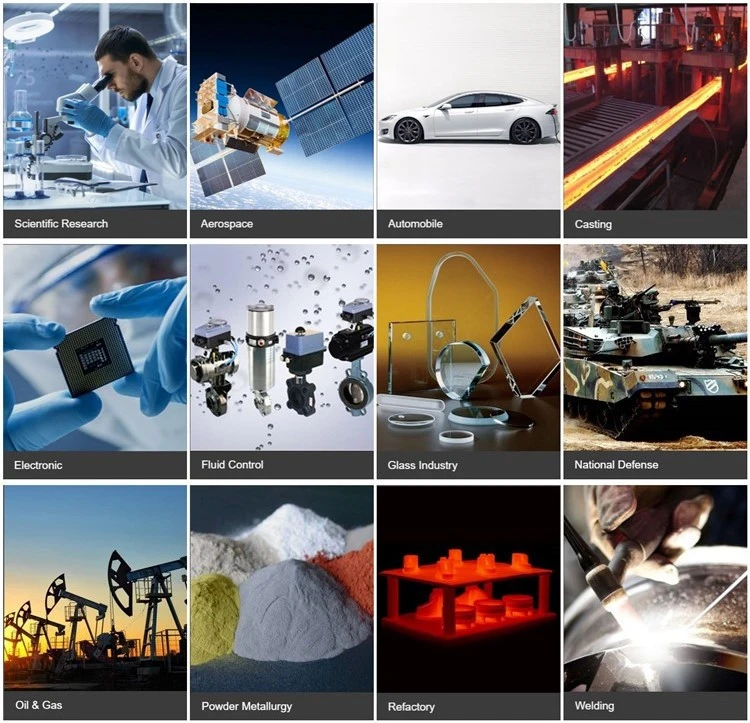

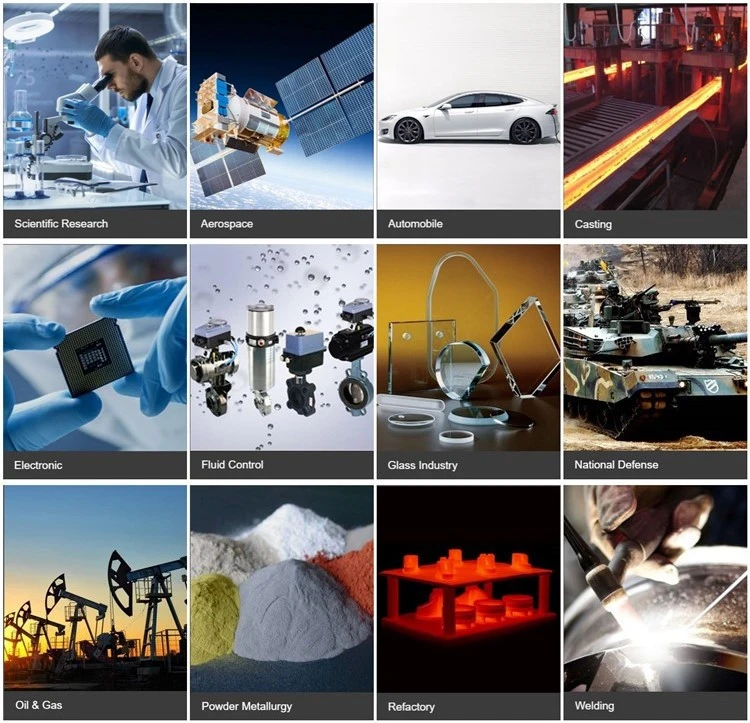

Bambalwa abantu abaziyo ukuba mangaphi na amashishini asebenzisa ii-ceramics zobugcisa mihla le. Iiseramikhi zobugcisa zizinto eziguquguqukayo ezinokuthi zisetyenziswe kumashishini amaninzi ngeenjongo ezahlukeneyo ezinomdla. Iiseramics zobugcisa zenzelwe usetyenziso oluhlukeneyo.

Ngenxa yokuba awukwazi ukuguquguquka kwezinto kwaye awuqondi ukuba iiseramikhi zobugcisa zingasetyenziswa kwishishini lakho, usenokungaqondi nokuba ishishini lakho lingaphumelela ukuba uqala ukusebenzisana nenye yeenkampani eziphambili zobugcisa zeseramikhi. Lixesha lokutshintsha oko kwaye uhlolisise onke amashishini axhamla kwiipropati ezizodwa zeekeramics zobugcisa.

Ngawaphi amashishini apho iiseramikhi zobugcisa zisetyenziswa?

Izinto ezimangalisayo zeseramikhi zobugcisa ziquka ukuguga okugqwesileyo, umgangatho ophezulu weempawu ze-thermal, ukomelela okuphezulu, ukuxinana okuphantsi, njl. Oku kwandisa ukusebenza kweeseramikhi zobugcisa kumashishini ahlukeneyo.

Ushishino lwelanga

Kwishishini lelanga, iikeramics zobugcisa zizinto ezithandwa kakhulu. Ziyakwazi ukumelana nobushushu kunye nomhlwa, zomelele kakhulu, kwaye ziyaqhuba kakhulu.

Ezi mpawu zenza i-ceramics yezoshishino ibe zixhobo ezibalulekileyo zokuvelisa iimveliso ezininzi zelanga, kubandakanya iiphaneli zelanga, abaqokeleli, iiseli kunye neebhetri.

Ishishini le-Aerospace

Iipropathi ezininzi ezinqwenelekayo zeekeramics zobugcisa zizenza zilungele ukusetyenziswa kwe-aerospace. Ezi mpawu ziquka ubunzima obuphantsi, ukuxhathisa kumaqondo obushushu aphezulu, ukunganyangeki kwe-corrosion, ukuzinza kweekhemikhali, ukugquma kombane, kunye nokumelana okugqwesileyo kokunxiba.

Xa kuziwa kwizicelo ze-aerospace, iiseramikhi zobugcisa zisetyenziselwa izikhuselo zokukhusela ukushisa, ukukhupha kunye neenkqubo ze-injini, kunye namacandelo e-injini yomoya, kunye nokubonelela ngenkxaso yesakhiwo kwizinto ezenzelwe ukubhabha ngesantya esiphezulu kakhulu.

Ushishino lweemoto

Kwishishini leemoto, ukuqina okugqwesileyo kunye nokuchasana nobushushu obuphezulu be-ceramics zobugcisa, phakathi kwezinye iimpawu ezininzi, zizathu eziphambili zokusetyenziswa kwazo. Kumzi mveliso weemoto, kukho iindidi ezimbini ezisisiseko zamacandelo e-ceramic:

I-ceramics esebenzayo: Kumacandelo asebenzayo anjengezinzwa ze-oksijini, iintlantsi, iiplagi ezikhanyayo, ii-sensors zokunkqonkqoza, izifudumezi ze-PTC, ulawulo lomgama wokupaka, iinkqubo zokutofa kwe-fuel, njl., ii-ceramics zobugcisa zisetyenziswa.

I-Ceramics yesakhiwo: Amalungu okwakhiwa kweemoto ezifana neediski ze-brake, inkxaso ye-catalyst, amacandelo epompo, izihlungi ze-particulate, njl.

Ishishini le-elektroniki

Ngaphandle kweekeramics zobugcisa, le marike ye-4.5 yezigidigidi zeedola ayinakuba khona. Phantse zonke izixhobo zombane onazo, kuquka iikhomputha, ii-smartphones, nomabonakude, ziqulethe izinto ze-ceramic. Kwishishini le-elektroniki, iiseramikhi zobugcisa ziyimfuneko ngenxa yokugquma, i-semiconducting, i-superconducting, imagnethi kunye neempawu zepiezoelectric.

Iiseramikhi zobugcisa zinokufumaneka kwii-capacitors, inductors, izixhobo zokukhusela iisekethe, iziboniso, iinkqubo zomsindo, kunye nezinye izinto ezininzi ze-elektroniki. Ii-electronics zanamhlanje bezingenakubakho ngaphandle kweeseramikhi zobugcisa.

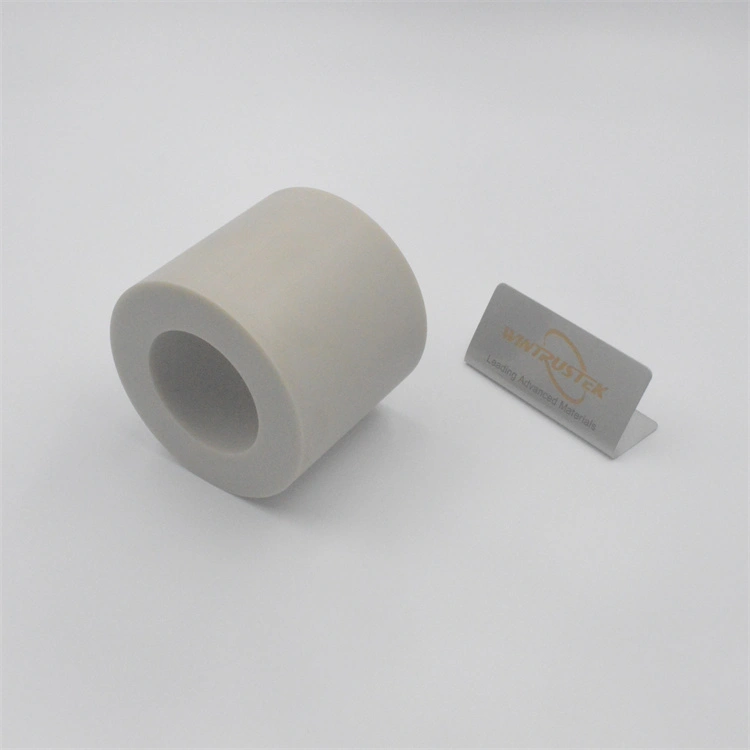

Ishishini leoli negesi

Izixhobo ze-oyile kunye ne-gas industry kufuneka zisebenze ngokufanelekileyo kwiindawo ezinobungozi kunye ne-abrasive. Ngoko ke, ii-ceramics zobugcisa zifanelekile kwizicelo ezinjalo. I-ceramics yobugcisa inokumelana nokushisa okuphezulu kunye noxinzelelo olunzima, okwenza kube yinto efanelekileyo yokusetyenziswa kweli shishini.

Ukongezelela, ngenxa ye-customizability ephezulu yeekeramics kunye nokuguquguquka oku kubonelela, umenzi onamava we-ceramics zobugcisa unokuvelisa i-compound eneempawu ezifanelekileyo kwisicelo esijoliswe kuyo. Oku kwenza ukuba iiseramikhi zobugcisa zibe lukhetho olubalaseleyo kuninzi lweemfuno zeshishini leoli negesi.

Ishishini lenkonzo yokutya

Iipropathi ezikhuselekileyo zokutya zeekeramics zobugcisa zenza ukuba zibe yinto ekhethekileyo kwishishini lenkonzo yokutya. Iiyunithi zethamo, izilayidi zedosi, izikhokelo zevalvu kunye nezihlalo, imida yokumisa kunye nezinto zokubamba, kunye nezixhobo zokwenza, ziqulethe iiseramikhi.