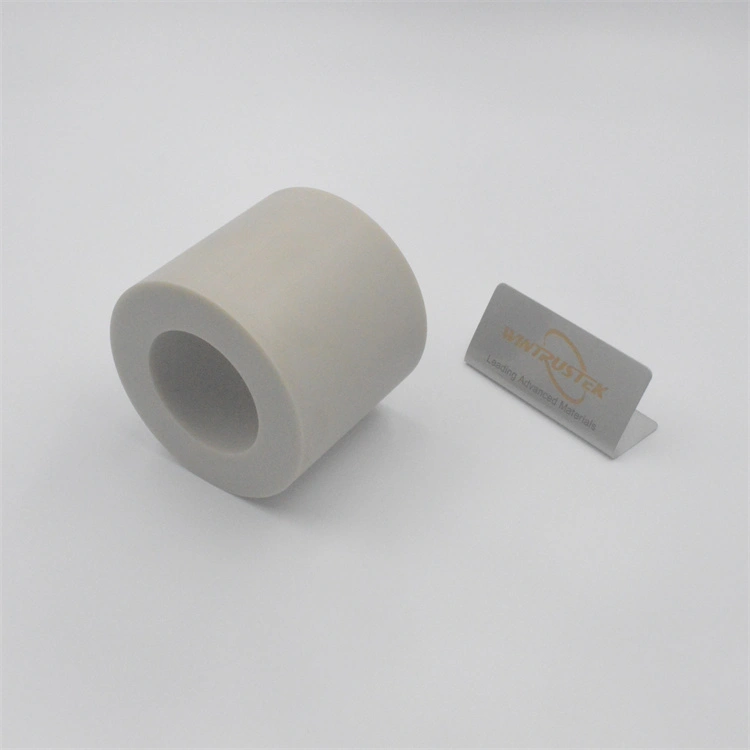

(Ceramic PowderE hlahisoa keWintrustek)

Ceramic phofoe entsoe ka likaroloana tsa ceramic le li-additives tse etsang hore ho be bonolo ho li sebelisa ho etsa likarolo. Sehlahisoa se tlamang se sebelisetsoa ho boloka phofo hammoho ka mor'a ho kopana, ha moemeli oa ho lokolla o etsa hore ho khonehe ho tlosa motsoako o kopantsoeng ho tloha ho compaction die ka boiketlo.

Mehlala ea lintho tse bonahalang

ALUMINA

Ceramic e nang le foromo ea lik'hemik'hale Al2O3 e bitsoa alumina. Lintho tse ka sehloohong tsa li-powders tsena ke sebopeho sa tsona, ho hloeka, ho thatafala, le sebaka se itseng sa holimo.

ALUMINIUM NITRIDE

Liindastering tsa semiconductor le tsa elektroniki, litšoaneleho tsena tsa mocheso le motlakase li bohlokoa haholo.

HEXAGONAL BORON NITRIDE

Hexagonal boron nitridee na le mokelikeli o motle oa motlakase, mocheso oa mocheso, le botsitso ba lik'hemik'hale.

ZYP

ZYP powder e entsoe ka zirconia e tsitsitsoeng ka yttrium oxide 'me ke phofo e ntle haholo, e sebetsang haholo.

Mekhoa ea Tlhahiso

TSAMAI/ TSAMA

Ho sila, ho tsejoang hape e le ho sila, ke mokhoa oa ho hlahisa phofo ea ceramic eo boholo ba karoloana ea ntho ea ceramic e fokotsoang ho fihlela e fetoloa hore e be phofo.

TEBELLO TŠEBELE

Mokhoa o mong o atileng oa ho hlahisa li-powders tsa ceramic ke tape casting. E sebelisoa ho hlahisa li-substrates tse kopanetsoeng tsa potoloho. Ntle le moo, e sebelisoa kahong ea li-capacitor tsa multilayer le meaho e kopaneng ea liphutheloana tsa potoloho. Ho lahla ho etsahala khafetsa holim'a sephutheloana ho sebelisoa phofo ea ceramic, solvent ea organic, le polymer binder. Teflon kapa ntho e 'ngoe e sa thupeng e sebetsa e le sebaka se tsamaisang thepa. Joale, ho sebelisoa ntlha ea thipa, motsoako oa phofo ea ceramic (slurry) o ajoa ho pholletsa le bokaholimo bo boreleli ho botenya bo reriloeng esale pele. Kamora ho omisoa, lera la motsoako oa phofo ea ceramic o lokisetsoa ho sebetsa.

KOPANANA

Ceramic phofo e fetoloa ka mokhoa ona ho tloha boemong ba eona ba granular ho ea ho e momahaneng le e teteaneng. Mokhoa ona o kopanya phofo ea ceramic, joalo ka ha lebitso le fana ka maikutlo. Ho hatella kapa ho hatella ho chesang ho ka sebelisoa ho kopanya likaroloana tsa ceramic.

EENTO MBOPI

Ente ea ente e sebelisoa ho hlahisa lisebelisoa tsa ceramic tse nang le li-geometri tse rarahaneng. Mokhoa ona o ka sebelisoa ho hlahisa thepa ea ceramic ka bongata bo boholo. Ho etsa ente ke ts'ebetso e fapaneng. E sebelisoa bakeng sa lirafshoa tsa oxide ceramics le li-non-oxide ceramics. Ho feta moo, e nepahetse haholo. Sehlahisoa sa ho qetela sa ho bopa ente ke sa boleng bo holimo.

TS'ELISO TS'OANE

Slip casting ke mokhoa oa tlhahiso ea phofo ea ceramic eo hangata e sebelisoang lipitsa tsa letsopa. Ka tloaelo, e sebelisoa ho etsa libopeho tseo ho leng thata ho li etsa ka lebili. Slip casting ke ts'ebetso e telele e ka nkang lihora tse 24. Ka lehlakoreng le letle, sehlahisoa se felileng se nepahetse ebile se ka tšeptjoa. Europe, slip casting e qalile lilemong tsa bo-1750, 'me Chaena, e qalile le ho feta. Ho emisoa ha phofo ea ceramic ho e nolofalletsa ho bokana joalo ka slip. Ka mor'a moo, hlobo e nang le porous e tlatsoa ka slip. Ha hlobo e omella, e etsa lera le tiileng ho tloha likheong.

TŠEBELETSO GEEL

Ho hlahisa li-gel ke ts'ebetso ea ho etsa phofo ea ceramic e qalileng Canada ka bo-1960. E hiriloe ho etsa libopeho tse rarahaneng tsa ceramic tse matla le tsa boleng bo holimo. Mokhoa ona, monomer, cross-linker, le free radical initiator li kopantsoe le phofo ea ceramic. Ka mor'a moo, motsoako o kenngoa ho fanyeha ha metsi. Ho eketsa boima ba motsoako, setlamo se seng se ntse se le teng se entsoe ka polymerized. Joale motsoako o fetoha gel. Motsoako oa gel o tšeloa ka har'a hlobo ebe o lumelloa ho tiisa moo. Ka mor'a ho tiisa, ntho e ntšoa ka hlobo ebe e omisoa. Sehlahisoa se felileng ke 'mele o motala oo ka mor'a moo o sintered.

TŠEBELETSO

Extrusion ke mokhoa oa ho etsa phofo ea ceramic e ka sebelisoang ho bopa thepa hore e be libopeho tse lakatsehang. Ho hula phofo ea ceramic ka lesela le nang le karolo e itseng ea sefapano. Ho hlahisa li-ceramics tse nang le li-cross-sections tse rarahaneng ho ka khoneha ka mokhoa ona. Ho feta moo, ha e sebelise matla a lekaneng ho li senya. Lihlahisoa tsa ho qetela tsa mokhoa ona li matla 'me li na le polishe e babatsehang ea holim'a metsi. Ka 1797, ts'ebetso ea pele ea extrusion e ile ea etsoa. Motho ea bitsoang Joseph Bramah o e entse. Extrusion e ka ba e futhumetseng, e phodileng kapa e chesang. Ka mocheso o phahameng ho feta mocheso oa thepa ea recrystallization, extrusion e chesang e etsahala. Extrusion e futhumetseng e etsahala ka holim'a mocheso oa kamore le ka tlase ho mocheso oa thepa e nchafatsang, athe extrusion e batang e etsahala ka mocheso oa kamore.