Mokhoa oa Atomization oa Khase

Lilemong tsa morao tjena, ka lebaka la tlhokahalo e ntseng e eketseha ea li-powders tsa tšepe 'marakeng, lirafshoa tse entsoeng ka boron nitride li se li tumme haholo bakeng sa ho sebelisoa ho atomization ea tšepe e qhibilihisitsoeng.

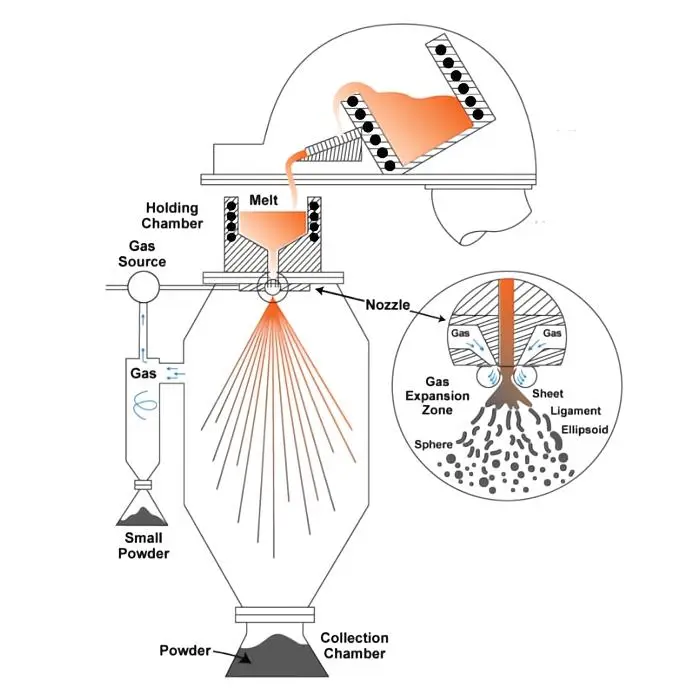

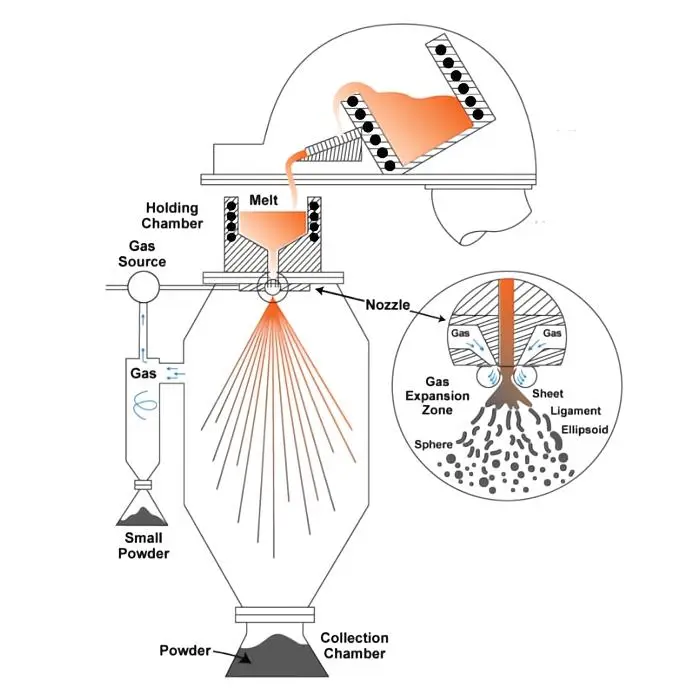

Atomization ke mokhoa oa ho fetola thepa e tiileng kapa e metsi hore e be boemong ba eona ba khase e sa lefelloeng. Mokhoa ona o atisa ho sebelisoa indastering ea tšepe e entsoeng ka tšepe ho etsa phofo e ntle ea tšepe ka thepa e kang aluminium, tšepe, tšepe e sa hloekang, le li-alloys tse kholo.

Mokhoa oa atomization oa tšepe e qhibilihisitsoeng e ka aroloa ka mekhahlelo e meraro e fapaneng.

Ntlha ea pele, o tla hloka ho tšela tšepe e qhibilihisitsoeng ka nozzle e entsoeng ka Boron Nitride (BN).

Ka mor'a moo, metsi a nang le khatello e phahameng ea metsi kapa khase a lokela ho sebelisoa ho hasa tšepe ea metsi.

Qetellong, bokella phofo ea tšepe ea boleng bo holimo e theohetseng tlase, 'me u e sebelise ho khatiso ea 3D le liindasteri tse ling tsa bohlokoa.

Atomization e ka etsoa ka mekhoa e mengata e fapaneng, ho kenyelletsa ka tšebeliso ea metsi le khase.

1. Atomization ea Metsi

Hangata, atomization ea metsi e sebelisoa ho etsa phofo ea tšepe, haholo-holo bakeng sa litšepe tse entsoeng ka tšepe. E ikarabella pakeng tsa 60 le 70 lekholong ea tlhahiso ea lefats'e ea phofo ea tšepe. The atomization ea metsi e ka boela ea sebelisoa ho etsa koporo e ngata, nickel, tšepe e sa hloekang, le phofo e bonolo ea makenete.

Atomization ea metsi e se e tumme haholo indastering ea phofo ea metallurgy hobane e theko e tlase ho feta mekhoa e meng. Ha e bapisoa le khase le lisebelisoa tse ling tsa jete, e sebelisa matla a fokolang ho sebetsa 'me e na le tlhahiso e phahameng. Ha o sebetsana le litšepe tse sebetsang le li-alloys, leha ho le joalo, atomization ea metsi ha e sebetse. Sena se fella ka hore ho thehoe atomization ea khase hammoho le mekhoa e meng ea atomizing.

2. Atomization ea Khase

The atomization ea khase e fapane le atomization ea metsi ka litsela tse 'maloa. Nakong ea ho arola tšepe ea metsi, atomization ea metsi e sebelisa li-jets tsa metsi, athe atomization ea khase e sebelisa khase ea lebelo le phahameng. Le hoja khatello ea seaplane e na le tšusumetso e kholo ho atomization ea metsi, ntlha ena ha e na karolo ea atomization ea khase. Ts'ebetso ea atomization ea khase e ka boela ea sebelisoa mefuteng e mengata e fapaneng ea lisebelisoa. Atomization ea khase e sebelisoa haholo ho metallurgy ea zinki, aluminium le lialloys tsa koporo. Sena se bakoa ke ho lakatseha ha likarolo tse boletsoeng ka holimo.

Ts'ebetsong ea atomization, litlhoko tsa nozzles ke tse latelang:

Ho na le mefuta e mengata ea lisebelisoa tse fumanehang bakeng sa ho sebelisoa ts'ebetsong ea atomization. Ho qala, e ka ba tikoloho ea khatello e tlase haholo kapa e nang le vacuum e phahameng e tlameha ho ba teng. Ho phaella moo, lisebelisoa tsa jete tse kang metsi kapa khase li hlokahala ka ho feletseng. Habohlokoa ka ho fetisisa, ts'ebetso ea atomization e ne e ke ke ea tsamaea hantle ntle le li-nozzles tse entsoeng hantle. Li-nozzles tse robehileng kapa tse koetsoeng li ka sitisa mokhoa oa ho hlahisa phofo, kahoo ho ba le li-nozzles tse entsoeng hantle ho bohlokoa. Ka hona, nozzle e hloka ho phethahatsa litlhoko tse boletsoeng ka holimo.

Matla a Phahameng: E le ho thibela mapetsong a li-nozzles tse sebelisoang ts'ebetsong ea atomization, lisebelisoa tse sebelisoang li tlameha ho ba le boima bo phahameng.

High Thermal Shock Stability: Lisebelisoa tse matla li sebelisoa ho etsa bonnete ba hore sehlahisoa se tla tsoela pele ho sebetsa ka mokhoa o phethahetseng le ha se pepesehetse mocheso o phahameng.

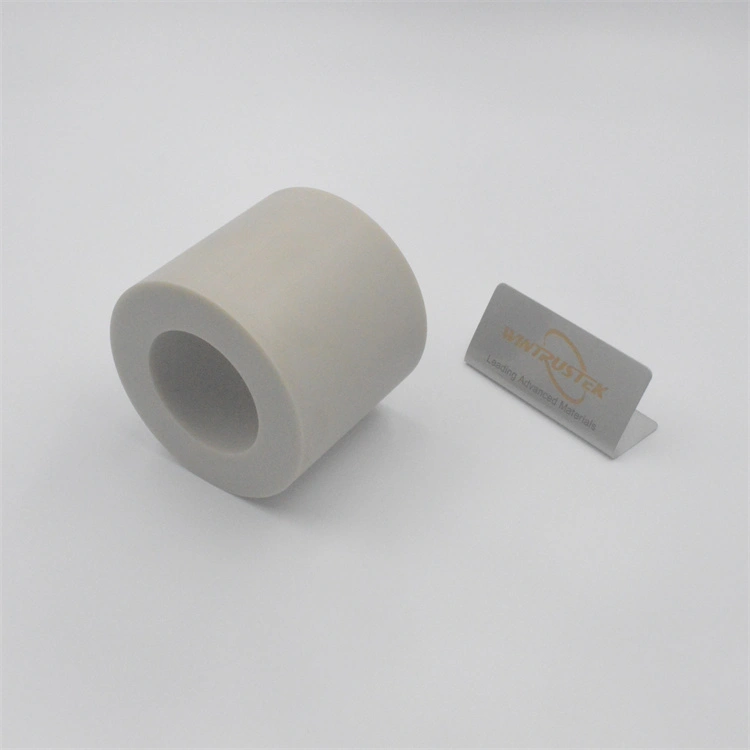

Ke thepa efe e etsang hore Boron Nitride e be sesebelisoa se loketseng bakeng sa nozzle ea atomizing ea tšepe?

Boron Nitride, Silicon Carbide, le Zirconia ke likarolo tse tharo tse etsang thepa ea rona e khethehileng ea BN ceramic composite. Ka lebaka la boima ba eona bo feteletseng le botsitso, thepa ena e loketse ho sebelisoa liindastering tse sebetsanang le tšepe e qhibilihisitsoeng. Mona ke litšobotsi tsa eona tse ntle:

Matla a kgabane

Ts'ebetso e ntle ea mocheso

E bonolo ho sebetsa

Ho fokotseha ho fokolang ho atomizer

Qetellong, li-ceramics tsa Boron Nitride li na le matla a tsotehang le ts'ebetso ea mocheso e tsitsitseng ka mokhoa o tsotehang, e leng se etsang hore e be khetho e nepahetseng bakeng sa ho etsa li-nozzles tse sebelisoang ho atomization ea tšepe e qhibilihisitsoeng.