(I-Ceramic PowderIkhiqizwe nguWintrustek)

I-Ceramic powderyakhiwe ngezinhlayiya ze-ceramic kanye nezithasiselo ezenza kube lula ukusetshenziselwa ukwenza izingxenye. I-ejenti ebophezelayo isetshenziselwa ukugcina impushana ihlangene ngemva kokuhlangana, kuyilapho i-ejenti yokukhulula yenza kube nokwenzeka ukususa ingxenye ehlangene emshinini wokuhlanganisa kalula.

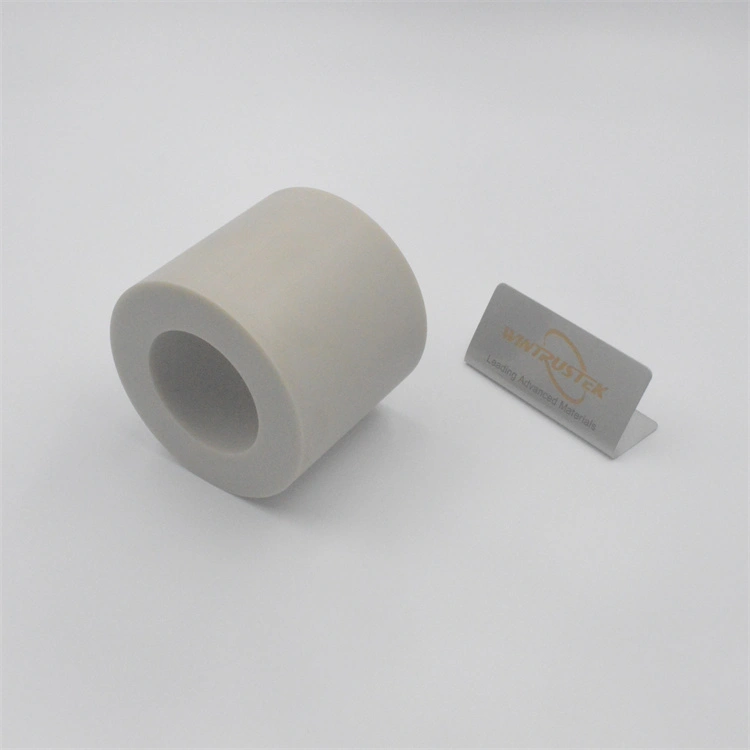

Izibonelo zezinto ezibonakalayo

U-ALUMINA

I-Ceramic enefomula yamakhemikhali i-Al2O3 ibizwa ngokuthi i-alumina. Izakhiwo eziyinhloko zalezi zimpushana isakhiwo sazo, ubumsulwa, ubulukhuni, nendawo ethile.

I-ALUMINIUM NITRIDE

Ezimbonini zesemiconductor neze-electronics, lezi zimpushana' izimfanelo ezishisayo nezikagesi zibaluleke kakhulu.

I-HEXAGONAL BORON NITRIDE

I-hexagonal boron nitrideinokufakwa kahle kukagesi, i-thermal conductivity, kanye nokuzinza kwamakhemikhali.

ZYP

I-ZYP powder yenziwe nge-zirconia ezinziswe ne-yttrium oxide futhi iyimpushana ecoliseke ngendlela emangalisayo, esebenza kakhulu.

Izindlela Zokukhiqiza

UKUGAYA/UKUGAYA

Ukugaya, okwaziwa nangokuthi ukugaya, kuyindlela yokukhiqiza impushana ye-ceramic lapho usayizi wezinhlayiyana ze-ceramic substance ize iguqulwe ibe yimpushana.

UKUSAKALISA KWAMATHEYISI

Enye inqubo evamile yokukhiqiza izimpushana ze-ceramic i-tape casting. Isetshenziswa ekukhiqizeni ama-substrates wesifunda ahlanganisiwe. Ukwengeza, isetshenziswa ekwakhiweni kwama-capacitor amaningi kanye nezakhiwo zephakheji yesekethe ehlanganisiwe. Ukusakaza kwenzeka ngokuphindaphindiwe endaweni yenethiwekhi kusetshenziswa impushana ye-ceramic, i-organic solvent, kanye ne-polymer binder. I-Teflon noma enye into engeyona intonga isebenza njengendawo yokuthwala. Bese, kusetshenziswa unqenqema lommese, inhlanganisela ye-ceramic powder (slurry) isatshalaliswa endaweni ebushelelezi ibe ukujiya okunqunywe kusengaphambili. Ngemuva kokoma, ungqimba lwengxube ye-ceramic powder lulungiselelwa ukusetshenzwa.

COMPACT

Impushana ye-Ceramic iguqulwa ngale nqubo isuka esimweni sayo esiyimbudumbudu iye kokuhlanganayo nokuminyene. Le nqubo ihlanganisa i-ceramic powder, njengoba igama liphakamisa. Ukucindezela okubandayo noma ukucindezela okushisayo kungasetshenziswa ukuhlanganisa izinhlayiya ze-ceramic.

UKUBONGA UMJOVO

Ukubumba komjovo kusetshenziselwa ukukhiqiza izinto ze-ceramic ezinamajiyometri ayinkimbinkimbi. Le nqubo ingasetshenziswa ukukhiqiza izinto ze-ceramic ngobuningi. Ukubumba umjovo kuyinqubo eguquguqukayo. Isetshenziselwa kokubili i-oxide ceramics kanye ne-non-oxide ceramics. Ngaphezu kwalokho, inembe kakhulu. Umkhiqizo wokugcina wokubumba umjovo usezingeni eliphezulu.

UKUSAKAZWA KWE-SLIP

I-Slip casting iyindlela yokukhiqiza i-powder ceramic evame ukusetshenziswa ezitsheni zobumba. Ngokuvamile, isetshenziselwa ukwenza izimo okunzima ukuzenza usebenzisa isondo. I-Slip casting inqubo ende engathatha amahora angama-24. Ngakolunye uhlangothi, umkhiqizo oqediwe unembile futhi uthembekile. E-Europe, ukukhishwa kwama-slip kuqale ngeminyaka yawo-1750s, futhi e-China, kubuyela emuva nakakhulu. Ukumiswa kwe-ceramic powder kuyenza ihlangane njengesiliphu. Isikhunta esinezimbotshana sibe sesigcwaliswa ngesiliphu. Njengoba isikhunta sesomile, sakha ungqimba oluqinile kusuka kuma-slips.

I-GEL CASTING

Ukukhipha i-gel kuyinqubo yokukhiqiza impuphu ye-ceramic eyaqala eCanada ngeminyaka yawo-1960. Isetshenziselwa ukwakha izimo ze-ceramic eziyinkimbinkimbi ezinamandla nezisezingeni eliphezulu kakhulu. Kule nqubo, i-monomer, i-cross-linker, ne-radical Initiator yamahhala ihlanganiswa ne-ceramic powder. Inhlanganisela ibe isifakwa ekumisweni kwamanzi. Ukwandisa ukuqina kwengxube, isibophezelo esivele sikhona senziwe i-polymerized. Inhlanganisela ibe isishintsha ibe ijeli. Ingxube yejeli ithululelwa esikhunjeni futhi ivunyelwe ukuqina lapho. Ngemuva kokuqiniswa, into iyasuswa esikhunjeni futhi yomiswe. Umkhiqizo oqediwe uwumzimba oluhlaza obuye ufakwe i-sintered.

EXTRUSTION

I-Extrusion inqubo yokwenza impushana ye-ceramic engase isetshenziselwe ukubumba impahla ibe yizimo ezifunwayo. Ukudonsa impushana ye-ceramic ngedayizi enesiphambano esithile. Ukukhiqizwa kwe-ceramics eneziphambano eziyinkimbinkimbi kungenzeka ngale nqubo. Ngaphezu kwalokho, ayisebenzisi amandla anele ezintweni ukuze iziqhekeze. Imikhiqizo yokugcina yale nqubo iqinile futhi inopende oncomekayo wangaphezulu. Ngo-1797, inqubo yokuqala ye-extrusion yenziwa. Umuntu ogama lakhe linguJoseph Bramah wakwenza. Ukukhipha kungase kufudumele, kuphole, noma kushise. Ezingeni lokushisa elingaphezu kokushisa kwe-recrystallization yezinto, i-hot extrusion iyenzeka. I-extrusion efudumele yenzeke ngaphezu kwezinga lokushisa legumbi nangaphansi kwezinga lokushisa le-recrystallization yezinto ezibonakalayo, kanti i-extrusion ebandayo yenzeke ekamelweni lokushisa.