(Brazing CeramicByakozwe naWintrustek)

Nk'uko Inkoranyamagambo ivuga iti: "Kwinjira mu bice bibiri by'icyuma uhura urwego rw'umuringa cyangwa inzika hagati y'ubuso bufatanye." Birashoboka cyane ko bakomoka ku gihe cy'igifaransa kuva mu kinyejana cya 16 bivuze ko "gutwika."

Mubyukuri, injijo ishonga kandi itemba hagati yibintu bibiri mugihe cyo kubagwa. Akunze kwitwa "utose," iyi nzira ni ngombwa, cyane cyane iyo iyo feramics. Muri iyi minsi, ibikoresho bitandukanye birashobora gukwa guhuzwa kugirango bikore ingingo hagati yabo; Ibikoresho bishonga ku bushyuhe buri hejuru ya 450 ° C bizwi nka Brazes, mugihe ashonga kubushyuhe buri munsi ya 450 ° C bizwi nkabagurisha.

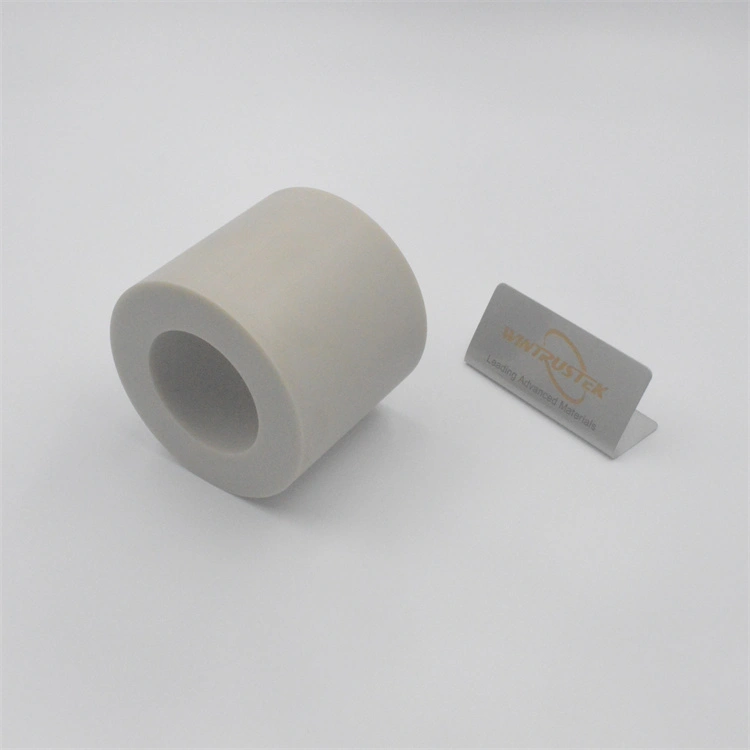

Uburyo bwashizweho bwo guhuza ceramics, feza ni uburyo bwa prop phese bukora neza cyane kugirango barebe ingingo na kashe. Ibigize bikoreshwa muri electronics ninganda zimodoka, kurugero, birashobora kuba byinshi byakozwe muburyo bwakozwe na tekinike ya Brazing.

Nkuko abantu bose babizi, ceramic zifite uburangare buke bwo guhangayika kandi biratoroshye kandi bikomeye. Bafite kandi umugongo muto. Ubumwe rero bwakozwe kugirango buhagarike umutekano wo kwibeshya niba bishoboka. Biyongereye ku bushyuhe nubwo bakoreshwa nkabasumoka. Ariko, dushobora noneho guhindura ibi bintu biranga intego zihariye, cyane cyane wo kongeramo fibre, whiskers, cyangwa izindi misa (gushimangira) ibice. Byongeye kandi, barashobora kunoza ibikwiye kubintu bitandukanye bitera imbaraga-biteye isoni.

Itandukaniro ryibanze hagatiBrazing Ceramicsn'ibyuma ni uko ceramic idashishimura nabenshi mubikoresho bisanzwe bya brazing. Ibi ni ukubera ibi bikoresho 'ibiranga umubiri, nkibikorwa byabo bya coscont na ionic. Byongeye kandi, biragoye gukora imiti ikomeye yo kunoza imiti kugirango itezimbere imbaraga kuva ceramic ari ndende cyane kuruta ibyuma. Mubuhanga butandukanye bushobora gukoreshwa mugukora ingingo zemewe, Brazing-ceramic birashoboka cyane kandi zisanzwe mubikorwa byo gukoresha ubukungu bitewe nubufatanye bwimikorere. Ceramic zambere zikora neza mubushyuhe bwicyumba, ntagaragaza imico yo kurwanya no guhiga (nta shishishwa).

Ikibazo cyo gukemura ikibazo cya serivisi ku bushyuhe bwo hejuru muri okiside cyangwa ibidukikije binini hamwe nibiranga ubukanishi byateye inkunga yatumye habaho ubwoko butandukanye bwubwoko buhanitse.

Hariho isuka ikomeye yo guteza imbere ibyifuzo bya ceramic muri moteri yubushyuhe no guta amashanyarazi atera amashanyarazi. Bose barashobora gusaba feramic bramic bramic. Ceramic hamwe na cte murwego rwibiti byo kwagura hasi cyane birasanzwe cyane kandi ikaze ko ibintu bikaze byo kurangiza neza brazing-ceramic. Gushushanya ingingo kugirango ushishikarizwe munsi yo kwikuramo nuburyo bumwe bukoreshwa mugufunga icyuho mu ndangagaciro za cte. Ubundi, iyo indangagaciro za cte zidasuzugura cyane, gukoresha ibikoresho byimbere birashobora gutanga inzibacyuke kuva hasi cyane kugeza agaciro gakomeye k'umutungo.

Uburyo bukurikira bukoreshwa mugushishikariza icyuma cyuzuye cyuma cya ceramics no kubanga hejuru:

1.. INZIRA RY'AMAZIBrazing-ceramicBikubiyemo kubanza gukoresha ibintu, mubisanzwe icyuma, hejuru yubusa mugihe gihuriweho nicyuma gisanzwe kidafite ibyuma bidashidikanyeho hejuru yubusa.

Ipati yicyuma ikora nkibintu bihurira icyuho hagati ya ceramic nicyuma. Bigomba kwitabwaho kugirango birinde ceramic gucibwa ninzobere zo mu kirere.

Igipfukisho kizwi cyane cya Molybdenum-Manganese kirasanzwe muri iri shuri. Gushushanya ceramic, uruvange rwibyatsi byakozwe byumwihariko bikoreshwa.

Nyuma yibyo, bitwitswe hafi 1500 ° C (2730 ° f) mu itanura rishingiye ku mbumbaro, ritera ibikoresho by'ibihuri by'ibihuri byo kwimuka ku ibyuma bikabifata hejuru.

Kubyuma byoherejwe, ubundi buryo bukoreshwa na bukoreshwa bukoresha imyuka yumubiri (PVD). Nyuma yaho, Brazing-ceraramic ikorwa ukoresheje indangagaciro zisanzwe zuzuye ibyuma bikwiranye nicyuma gikeneye guhuzwa.

2. Ukoresheje ibyuma bifatika byuzuye hamwe nibice byihariye byoherejwe kugirango bakonge ceramic muburyo butaziguye. Gutobora no kumesa byongerewe igihe ibyuma bikabije kubice bigize Ceramic byongewe kuri feri isanzwe ya feza.

Kubera iyo mpamvu, ibyuma bitwara neza na ogisijeni, kimwe na titanium, aluminium, hafnium, hafnium, sitnium, silicon, fasha manganeri, tanga na mangane, fasha muri litide ya branzide itontoma.

Gutesha agaciro Silicon Carbide cyangwa Silicon Nitride ifashwa nibyuma bitwara na silicon, karubone, cyangwa azote.