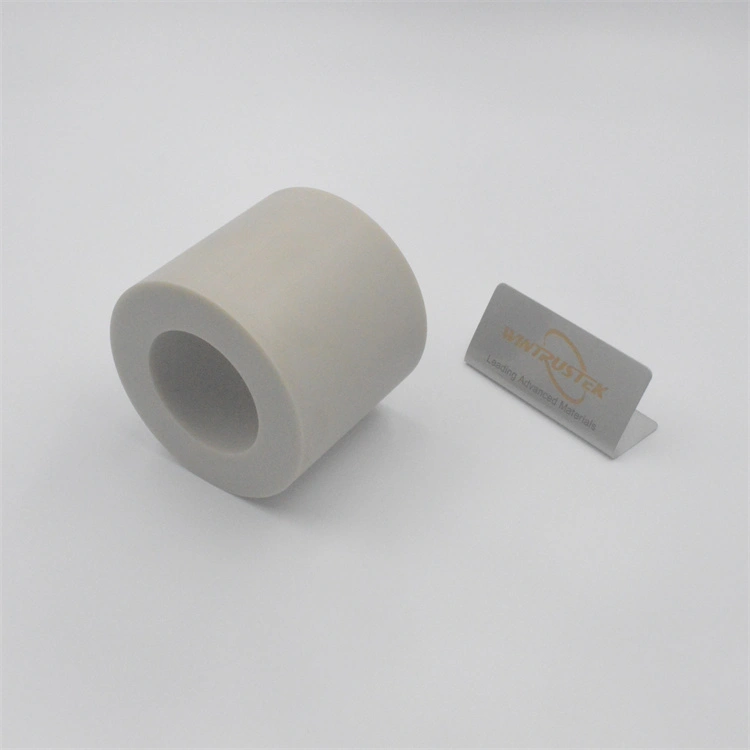

(Ceramic ntụ ntụMepụtara yaWintrustek)

Ceramic ntụ ntụbụ ihe mejupụtara seramiiki na ihe mgbakwunye na-eme ka ọ dị mfe iji mee ihe. A na-eji ihe eji eme ihe na-ejikọta ya na ntụ ntụ mgbe emechara, ebe onye na-ahapụ ya na-eme ka o kwe omume iwepụ ihe mgbagwoju anya site na nchịkọta na-anwụ anwụ na-adị mfe.

Ihe atụ ihe

ALUMINA

A na-akpọ seramiiki nwere usoro kemịkalụ Al2O3 alumina. Ihe ndị bụ isi nke ntụ ntụ ndị a bụ nhazi ha, ịdị ọcha, ike siri ike, na mpaghara elu kpọmkwem.

ALUMINUM NITRIDE

N'ime ụlọ ọrụ semiconductor na eletrọnịkị, àgwà ọkụ na ọkụ eletrik ka a na-eji ntụ ntụ ndị a akpọrọ ihe.

HEXAGONAL BORON NITRIDE

Hexagonal boron nitridenwere ezigbo mkpuchi eletriki, conductivity thermal, na nkwụsi ike kemịkal.

ZYP

A na-eme ntụ ntụ ZYP site na zirconia nke ejiri yttrium oxide kwụsie ike ma bụrụ ntụ ntụ na-enweghị atụ, na-emegharị ahụ nke ukwuu.

Ụzọ nrụpụta

MILLING/ NA-EGWU

Egwe ọka, nke a makwaara dị ka egweri, bụ ụzọ a na-esi emepụta ntụ ntụ seramiiki nke na-ebelata nha nke ihe seramiiki ruo mgbe ọ gbanwere ghọọ uzuzu.

Mkpokọta teepu

Usoro ọzọ na-ewu ewu maka imepụta ntụ ntụ seramiiki bụ nkedo teepu. A na-etinye ya n'ọrụ na mmepụta nke substrates sekit agbakwunyere. Na mgbakwunye, a na-eji ya arụ ọrụ n'ịrụ multilayer capacitors yana ngwungwu sekit agbakwunyere. Nkedo na-ewere ọnọdụ ugboro ugboro n'elu ihe na-ebu ihe na-eji ntụ ntụ seramiiki, ihe mgbaze organic na ihe nkedo polymer. Teflon ma ọ bụ ihe ọzọ na-abụghị osisi na-eje ozi dị ka elu ebu. Mgbe ahụ, na-eji nsọtụ mma, a na-ekesa ngwakọta ntụ ntụ seramiiki (slurry) n'ofe dị larịị ka ọ bụrụ nke a kara aka. Mgbe akpọchara, a na-akwado oyi akwa nke ngwakọta ntụ ntụ seramiiki maka nhazi.

Kọmpat

A na-agbanwe ntụ ntụ seramiiki site na usoro a site na steeti granular ya gaa na nke jikọrọ ọnụ na nke siri ike. Usoro a na-ejikọta ntụ ntụ seramiiki, dị ka aha ahụ na-egosi. Enwere ike iji ịpị oyi ma ọ bụ ịpị ọkụ na-ejikọta ihe ndị dị na seramiiki.

NKWUKWU INJECTION

A na-eji ịkpụzi injection na-emepụta ihe seramiiki nwere ọdịdị geometric dị mgbagwoju anya. Enwere ike iji usoro a mepụta ihe seramiiki n'ọtụtụ buru ibu. Ịkpụzi injection bụ usoro dị iche iche. A na-eji ya maka seramiki oxide na seramiki na-abụghị oxide. Na mgbakwunye, ọ bụ nke ukwuu kpọmkwem. Ngwaahịa ikpeazụ nke ịkpụzi injection dị oke mma.

Mwepu nkedo

Nkedo nkedo bụ usoro mmepụta seramiiki ntụ ntụ nke a na-ejikarị arụ ọrụ na ite. Ọ na-adịkarị, a na-eji ya emepụta ụdị nke siri ike iji wiil. Nkedo nkedo bụ usoro dị ogologo nke nwere ike were ihe ruru awa iri abụọ na anọ. N'akụkụ gbakwunyere, ngwaahịa emechara bụ nke ziri ezi na ntụkwasị obi. Na Europe, ihe nkedo na-amị amị malitere laa azụ na 1750s, na na China, ọ maliterela azụ karịa. Nkwụsịtụ nke ntụ ntụ seramiiki na-enyere ya aka ịbịakọta ọnụ dị ka mwepu. A na-ejizi ihe e ji amịpụta mee jupụta ebu nwere oghere. Ka ebu ahụ na-akpọnwụ, na-eme akwa oyi akwa si na slips.

NKWUKWU GEL

Ihe nkedo gel bụ usoro imepụta ntụ ntụ nke malitere na Canada na 1960s. A na-eji ya emepụta ụdị seramiiki dị mgbagwoju anya nke siri ike ma dị mma. Na usoro a, a na-ejikọta monomer, cross-linker, na free radical initiator na seramiiki ntụ ntụ. A na-agbakwunye ngwakọta ahụ na nkwusioru mmiri. Iji mee ka ngwakọta ahụ sie ike, ihe nkedo dị ugbu a bụ polymerized. Nchikota ahụ wee ghọọ gel. A na-awụnye ngwakọta gel n'ime ihe ebu ma kwe ka ọ sie ike n'ebe ahụ. Mgbe emesiri ike, a na-ewepụ ihe ahụ site na ebu ma kpoo ya. Ngwaahịa emechara bụ ahụ akwụkwọ ndụ akwụkwọ ndụ nke emesịa mebie ya.

Mpụga

Extrusion bụ usoro maka ime ntụ ntụ seramiiki nke enwere ike iji mee ihe ahụ ka ọ bụrụ ọdịdị achọrọ. Na-adọta seramiiki ntụ ntụ site na ịnwụ na otu akụkụ obe. Mmepụta nke ceramik nwere akụkụ obe dị mgbagwoju anya ga-ekwe omume na usoro a. Ọzọkwa, ọ naghị etinye ike zuru oke na ihe ndị ahụ iji gbawaa ha. Ngwaahịa ikpeazụ nke usoro a siri ike ma nwee ncha elu nke kwesịrị ịja mma. N'afọ 1797, e mere usoro extrusion mbụ. Otu onye aha ya bụ Joseph Bramah mere ya. Extrusion nwere ike ịdị ọkụ, dị jụụ, ma ọ bụ na-ekpo ọkụ. N'ebe okpomọkụ dị elu karịa okpomọkụ recrystallization nke ihe, extrusion dị ọkụ na-ewere ọnọdụ. Ọkụ ọkụ na-ekpo ọkụ na-ewere ọnọdụ n'elu ụlọ okpomọkụ yana n'okpuru okpomọkụ recrystallization nke ihe onwunwe, ebe oyi extrusion na-eme na ụlọ okpomọkụ.