(Brazing CeramicTsim los ntawmWintrustek)

Raws li phau ntawv txhais lus, Brazing yog "kev koom tes ntawm ob daim hlau los ntawm fusing ib txheej ntawm brass lossis spelter ntawm thaj chaw sib ze." Nws yog feem ntau yuav ua rau muaj kev cuam tshuam ntawm Fabkis lub sij hawm los ntawm 16 xyoo pua uas txhais tau tias "mus hlawv."

Hauv cov ntsiab lus, ib lub ntsej muag melts thiab ntws ntawm ob daim ntawm cov khoom thaum lub sijhawm ua haujlwm. Feem ntau hu ua "kev ntub dej," tus txheej txheem no yog qhov tseem ceeb, tshwj xeeb tshaj yog thaum Brazing Ceramics. Cov hnub no, ntau yam ntaub ntawv tuaj yeem fused los tsim cov pob qij txha nruab nrab ntawm lawv; Cov ntaub ntawv uas yaj ntawm qhov kub tshaj 450 ° C yog lub npe hu ua brazes, thaum cov uas yaj ntawm qhov kub hauv qab 450 ° C yog cov hu ua cov tub rog.

Ib txoj kev tsim tsa rau txoj kev ua raws cov lus cog lus, Brazing yog cov txheej txheem theem ua haujlwm uas ua haujlwm tshwj xeeb rau kev tsim cov pob qij txha thiab ntsaws ruaj ruaj. Cheebtsam uas siv rau hauv cov khoom siv hluav taws xob thiab kev lag luam hauv tsheb, piv txwv, tuaj yeem yooj yim ua kom muaj cov txheej txheem cranzque.

Raws li txhua tus paub, ceramics muaj kev ua siab ntev rau cov kev nyuaj siab tensile thiab muaj nkig thiab tsis yeem. Lawv kuj muaj kev du ncauj me me. Ceramics yog li ntawd ua rau muaj kev ntxhov siab hauv compression yog tias ua tau. Lawv muaj kev ntxim yuav ua rau thermal poob siab txawm tias lawv tau ua haujlwm raws li cov tshuaj insulators thermal. Txawm li cas los xij, peb tuaj yeem hloov cov yam ntxwv tshwj xeeb no kom haum cov hom phiaj tshwj xeeb, tshwj xeeb yog los ntawm kev ntxiv cov fibers, whiskers, lossis lwm yam loj-txhawb nqa (txhawb) cov lus. Ib qho ntxiv, lawv tuaj yeem txhim kho lawv qhov kev tsim nyog rau ntau yam kev siv los ntawm kev ua tiav cov txheej txheem-indles cov txheej txheem kev hloov.

Thawj qhov sib txawv ntawmCeramics CeramicsThiab cov hlau yog qhov ceramics no tsis yog wetted los ntawm feem ntau ntawm cov khoom lag luam brazing. Qhov no yog vim cov ntaub ntawv no 'ua rau cov yam ntxwv ntawm lub cev, xws li lawv cov kev sib cav sib luag thiab ionic. Ntxiv mus, nws yog qhov nyuaj los tsim cov tshuaj sib txuas rau txhim kho admesion txij li ceramics txij li ceramics ntau dua thermodynamically ruaj khov dua li cov hlau. Ntawm ntau cov tswv yim uas tuaj yeem siv los tsim cov pob qij txha uas siv tau, Brazing-ceramic yog qhov tseem ceeb tshaj plaws ntawm kev siv cov ceramics tam sim no vim tias lawv cov nyiaj txiag tseem ceeb. Ua ntej Ceramics ua haujlwm tau ua haujlwm zoo nyob rau hauv chav tsev kub, ua kom cov kev coj ua tsis kam thiab insulating zoo (tsis muaj kev ceeb toom).

Qhov teeb meem ntawm kev cuam tshuam nrog cov kev pabcuam ntawm cov kev pabcuam siab nyob rau hauv oxidizing lossis xeb ib puag ncig nrog cov khoom siv cov khoom siv tseem ceeb dua.

Muaj lub laub muaj zog los tsim kho cov ntawv thov rau cov ceramic hauv Thermial Engines thiab khib nyiab ntawm cov nroj tsuag uas tsim hluav taws xob. Txhua tus kuj yuav tsum muaj ceramic branzing. Ib tug ceramic nrog CTE nyob rau hauv cov kab ke ntawm qee cov me me-nthuav dav hlau tsis tshua muaj tshwm sim rau cov kev ua tiav kev ua tiav brazing-ceramic. Kev tsim cov pob qij txha kom raug kev ntxhov siab nyob rau hauv compression yog ib txoj kev nquag siv los kaw qhov sib txawv hauv CTE qhov tseem ceeb. Lwm txoj kev, thaum CTE qhov tseem ceeb tshaj plaws, kev siv cov ntaub ntawv nruab nrab tuaj yeem muab kev maj mam hloov ntawm qhov qis tshaj plaws ntawm cov cuab yeej.

Cov hau kev hauv qab no tau ua haujlwm los txhawb nqa hlau lub chaw ntub dej ntawm Ceramics thiab Adherence:

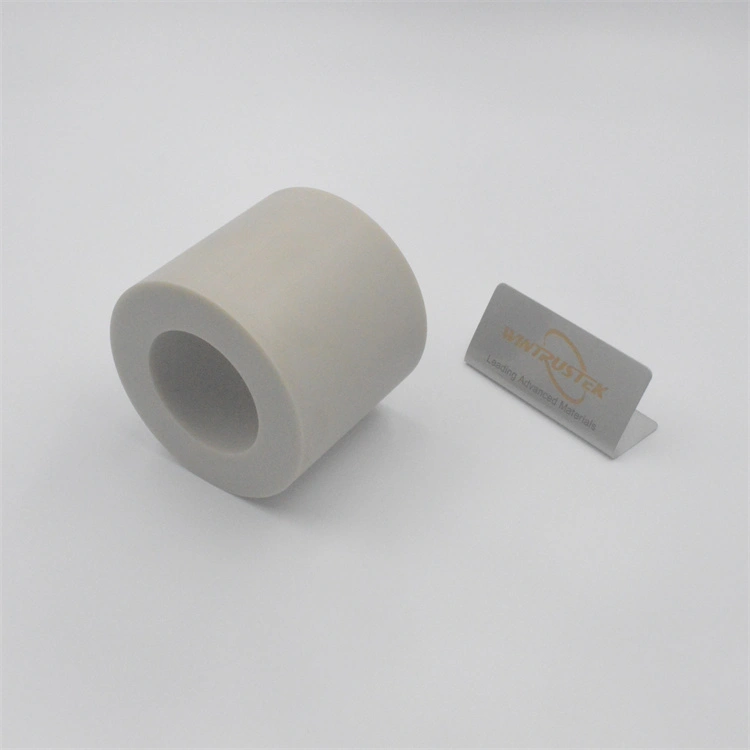

1. Kev tsis ncajBrazing-ceramicKoom nrog ua ntej thov cov khoom siv, feem ntau cov hlau, rau cov ceramic sib koom ua ke uas tuaj yeem raug muab pov tseg los ntawm tus qauv cov hlau tsis muaj cov hlau ua kom tsis txhob ntub cov chaw muaj hluav taws xob.

Cov txheej txheem hlau tawv ua cov khoom uas cov khoom uas txuas ntawm qhov sib txawv ntawm ceramic thiab hlau. Yuav tsum tau saib xyuas kom tiv thaiv kom tiv thaiv cov ceramic los ntawm kev tawg los ntawm cov txheej txheem sintering thaum tshav nrawm.

Lub ntsej muag zoo nkauj molybdenum-mangance txheej yog nyob hauv cov chav kawm no. Txhawm rau pleev xim rau cov ceramic, kev sib xyaw ntawm tshwj xeeb tau muaj hmoov muaj hmoov.

Tom qab hais tias, nws yog hlawv ntawm kwv yees li 1500 ° C (2730 ° F) hauv cov khoom siv hydrogen kom tau tsiv mus rau cov hlau thiab muab tso rau saum npoo.

Rau cov pob txha me me, lwm yam kev siv cov txheej txheem siv lub cev siv hluav taws xob (pvd). Tom qab ntawd, Brazing-ceramic yog nqa tawm siv cov chaw muab tub lim hlau cov hlau uas tsim nyog rau cov hlau uas yuav tsum tau txuas nrog.

2. Siv cov chav ua haujlwm nquag nrog cov hlau sib txuas nrog cov khoom sib txuam tshwj xeeb rau lub ntsej muag ci ci ncaj qha. Kev ntub dej thiab cov nplaum tau txhim kho thaum muaj kev sib txuam nrog kev sib txawv rau cov ceramic cov chaw ua haujlwm tau ntxiv rau cov qauv nyiaj-raws li cov alloys.

Vim tias qhov no, cov hlau uas hnov cov muaj zog nrog cov pa, xws li cov taum, ntshav, ntsiag to

Wetting silicon carbide lossis silicon nitride yog pab los ntawm cov hlau uas hnov nrog silicon, carbon, lossis nitrogen.