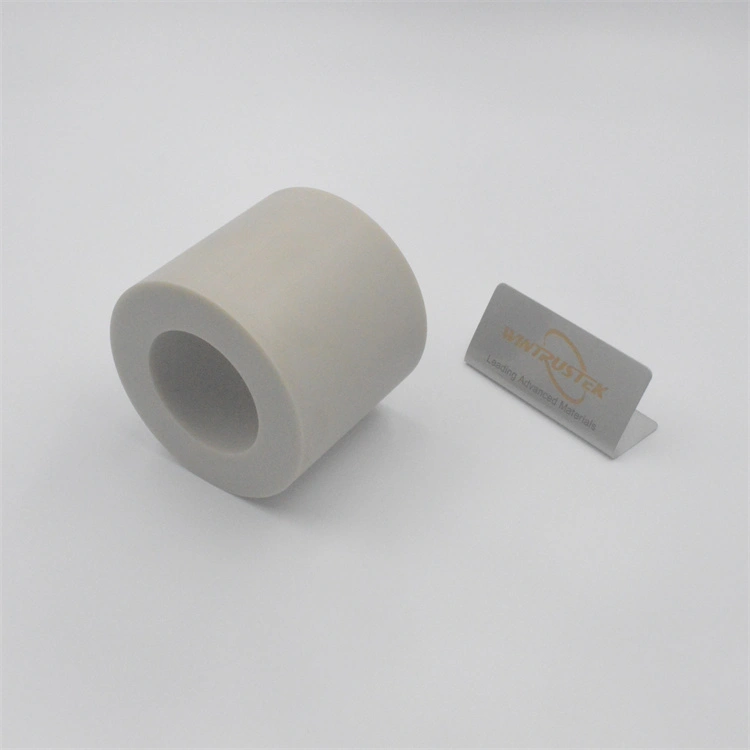

(Ceramic PowderProduced byWintrustek)

Ceramic podainoumbwa neceramic particles uye zvinowedzera zvinoita kuti zvive nyore kushandisa kugadzira zvikamu. Mushonga unosungirira unoshandiswa kuchengetedza hupfu pamwe chete mushure mekubatana, nepo mumiriri wekusunungura anoita kuti zvibvire kubvisa chikamu chakasungirirwa kubva kune compaction kufa zviri nyore.

Mienzaniso yezvinhu

ALUMINA

Ceramic ine kemikari formula Al2O3 inonzi alumina. Zvinhu zvekutanga zvehupfu idzi chimiro chadzo, kuchena, kuoma, uye nzvimbo yakatarwa.

ALUMINIUM NITRIDE

Mune semiconductor uye maindasitiri emagetsi, aya mapoda 'anopisa uye emagetsi maitiro anonyanya kukosha.

HEXAGONAL BORON NITRIDE

Hexagonal boron nitrideine magetsi ekudzivirira zvakanaka, conductivity yekupisa, uye kugadzikana kwemakemikari.

ZYP

ZYP hupfu inogadzirwa nezirconia yakagadzikiswa neyttrium oxide uye ihwo hupfu hwakatsetseka zvisingaite, hunoita kunyungudika.

Manufacturing Nzira

KUGAYA/KUGAYA

Kugaya, kunozivikanwawo sekugaya, inzira yekugadzira hupfu hweceramic umo saizi yechinhu checeramic inoderedzwa kusvika yashandurwa kuita hupfu.

TAPE CASTING

Imwe nzira yakapararira yekugadzira ceramic hupfu ndeye tepi casting. Inoshandiswa mukugadzirwa kweiyo integrated circuit substrates. Pamusoro pezvo, inoshandiswa mukuvaka kwema multilayer capacitors uye akasanganiswa edunhu mapakeji zvimiro. Kukanda kunodzokororwa kunoitika panzvimbo inotakura uchishandisa ceramic poda, organic solvent, uye polymer binder. Teflon kana chimwe chinhu chisina tsvimbo chinoshanda semutakuri wepamusoro. Zvadaro, uchishandisa mupendero webanga, iyo ceramic poda musanganiswa (slurry) inogovaniswa munzvimbo yakatsetseka kusvika kune yakatemerwa ukobvu. Mushure mekuoma, musanganiswa weceramic powder musanganiswa unogadzirirwa kugadziriswa.

COMPACT

Ceramic poda inoshandurwa nenzira iyi kubva kune granular state kusvika kune yakabatana uye yakaoma. Iyi nzira inobata ceramic poda, sekureva kunoita zita. Kutsikirira kunotonhora kana kupisa kudzvanya kunogona kushandiswa kugadzira zvidimbu zveceramic.

JEkiseni KUUMBISA

Jekiseni molding inoshandiswa kugadzira ceramic zvinhu zvine yakaoma geometries. Iyi nzira inogona kushandiswa kugadzira zvinhu zveceramic muhuwandu hukuru. Jekiseni molding inzira inosiyana-siyana. Inoshandiswa kune ese ari maviri oxide ceramics uye isiri-oxide ceramics. Mukuwedzera, yakanyatsojeka. Iyo yekupedzisira chigadzirwa chejekiseni molding ndeyemhando yepamusoro.

SLIP CASTING

Slip casting ihupfu ceramic kugadzira nzira iyo inowanzo shandiswa muhari. Kazhinji, inoshandiswa kugadzira zvimiro zvakaoma kugadzira uchishandisa vhiri. Slip casting inzira yakareba iyo inogona kutora kusvika kumaawa makumi maviri nemana. Pamusoro pezvakanaka, chigadzirwa chakapedzwa chakarurama uye chakavimbika. MuEurope, slip casting yakatanga kusvika kuma1750s, uye muChina, inodzokera kumashure zvakanyanya. Kumiswa kwehupfu hweceramic kunoita kuti iuye pamwe chete seanotsvedza. Iyo porous mold inobva yazadzwa neslip. Sezvo mold inomesa, ichiita jira rakasimba kubva pamashizha.

GEL CASTING

Gel casting ndeye ceramic poda yekugadzira maitiro ayo akatanga muCanada muma1960s. Inoshandiswa kugadzira yakaoma ceramic maumbirwo akasimba uye emhando yepamusoro. Mukuita uku, monomer, cross-linker, uye yemahara radical initiator inosanganiswa neceramic poda. Iko kusanganiswa kunozowedzerwa kune kumiswa kwemvura. Kuwedzera kuoma kwemusanganiswa, binder inenge iripo kare inonzi polymerized. Iko kusanganiswa kunozoshandura kuita gel. Iyo gel musanganiswa inodururwa muforoma uye inobvumirwa kusimba ipapo. Mushure mekuoma, chinhu chacho chinobviswa kubva muhutu uye chakaomeswa. Chigadzirwa chakapedzwa muviri wakasvibira unozoitwa sintered.

EXTRUSTION

Extrusion inzira yekugadzira hupfu hweceramic inogona kushandiswa kuumba zvinhu kuti zvive maumbirwo anodiwa. Kudhonza hupfu hweceramic kuburikidza nefa ine imwe muchinjiko-chikamu. Kugadzirwa kweceramics neakaomesesa-muchinjika-zvikamu zvinogoneka nehunyanzvi uhu. Uyezve, haipe simba rakakwana pazvinhu kuti zviparadze. Zvigadzirwa zvekupedzisira zveiyi nzira yakasimba uye zvine inoyemurika pamusoro pe polish. Muna 1797, yekutanga extrusion maitiro akaitwa. Munhu ainzi Joseph Bramah akazviita. Extrusion inogona kudziya, kutonhora, kana kupisa. Pane tembiricha yakakwira kupfuura iyo tembiricha yerecrystallization tembiricha, inopisa extrusion inoitika. Inodziya extrusion inoitika pamusoro pekamuri tembiricha uye pazasi tembiricha yekudzoreredza tembiricha, nepo kutonhora extrusion kunoitika pakamuri tembiricha.